Fitness For Service Approach in The Oil and Gas Industry

- August 9, 2022

- Posted by: Velosi Author

- Categories: Engineering, Insights

Fitness For Service Approach in The Oil and Gas Industry

What is fitness for service – FFS

Fitness-for-Service (FFS) is also known as Fitness-for-Purpose, it is an assessment conducted utilizing the best-practice industry standards. The FFS assessment approach is intended to evaluate the structural integrity of an asset/component to identify whether the asset/component is suitable for its assigned purpose. It conducts a quantitative engineering measure of structural integrity and is a well-known component of asset integrity management. These assessments are utilized to highlight any assistance needed for the substitution or repair of components/assets and their methodology directly constitutes the structural integrity of plant assets/components.

Furthermore, a Fitness-for-Service procedure allows industry professionals to construct informed decisions regarding the capability of the equipment to continue operating despite having any flaws or damage. Although many industry standards mark some sort of FFS assessment, the American Petroleum Institute (API) has compiled the best practices into a single, modular assessment standard (API 579-1), which has become an authoritative publication on FFS.

FFS serves as an analytical basis to identify flaw acceptance limits and enables the industry experts to distinguish between acceptable and unacceptable flaws and damage by the industry-recognized and widely accepted efficient engineering practices.

Let’s have a closer look into the benefits of Fitness- for- Service

- Utilize plant life management with life extension programs

- Minimize unnecessary repair and substitutions requirements

- Apply the process of design, fabrication, and operations

- Encourage higher standards of safety and availability of equipment

- Efficiently determine residual life of equipment/asset

- Incorporate previous knowledge and findings to optimize maintenance and inspection

- Maintain mechanical integrity of assets

- Reduce operational and maintenance cost

- Reduce downtimes

- Construct detailed report with run-repair/replace decision

- Regulate effective monitoring methods

Importance of fitness for service

Fitness-for-Service assessment utilizes all levels as part of a lifetime of the power plant to increase availability, reliability, efficiency, and safety. The acceptance of API 579/ASME FFS-1 is expanding across the energy sector and other leading industries. Due to the functionality of fitness-for-service, specific methods apply to several components for a wide range of damage mechanisms. If fitness-for-service assessment capabilities are not a part of the maintenance program, the preparation required to perform FFS assessments may result from a delay in resuming a critical asset on time.

FFS assessment techniques apply to several damage types such as:

- Local Thin Areas (LTA’s)

- Cracks

- Creep Damage

- Dents

Powerful analytical tools enable operators to keep the plant running safely. It is to note that engineers must be thoroughly familiar with API RP-579 and its implementation before using any of the FFS techniques.

Importance of FFS with Velosi

At Velosi, fitness for service assessment is usually under measurable engineering appraisals that are conducted to demonstrate the structural integrity of an in-service component that may comprise a flaw or damage. Our FFS assessments adhere to international standards such as ASME B31G, BS 7910, API 579-1/ASME FFS-1, and others.

Velosi’s experience comprehends assessment of the following damage mechanisms:

- Brittle Fracture

- General Metal Loss

- Local Metal Loss

- Pitting Corrosion

- Blisters and HIC/SOHIC Damage

- Weld Misalignment and Shell Distortions

- Crack-Like Flaws

- High-Temperature Operation and Creep

- Fire Damage

- Dent, Gouge and Dent Gouge Combinations

- Laminations

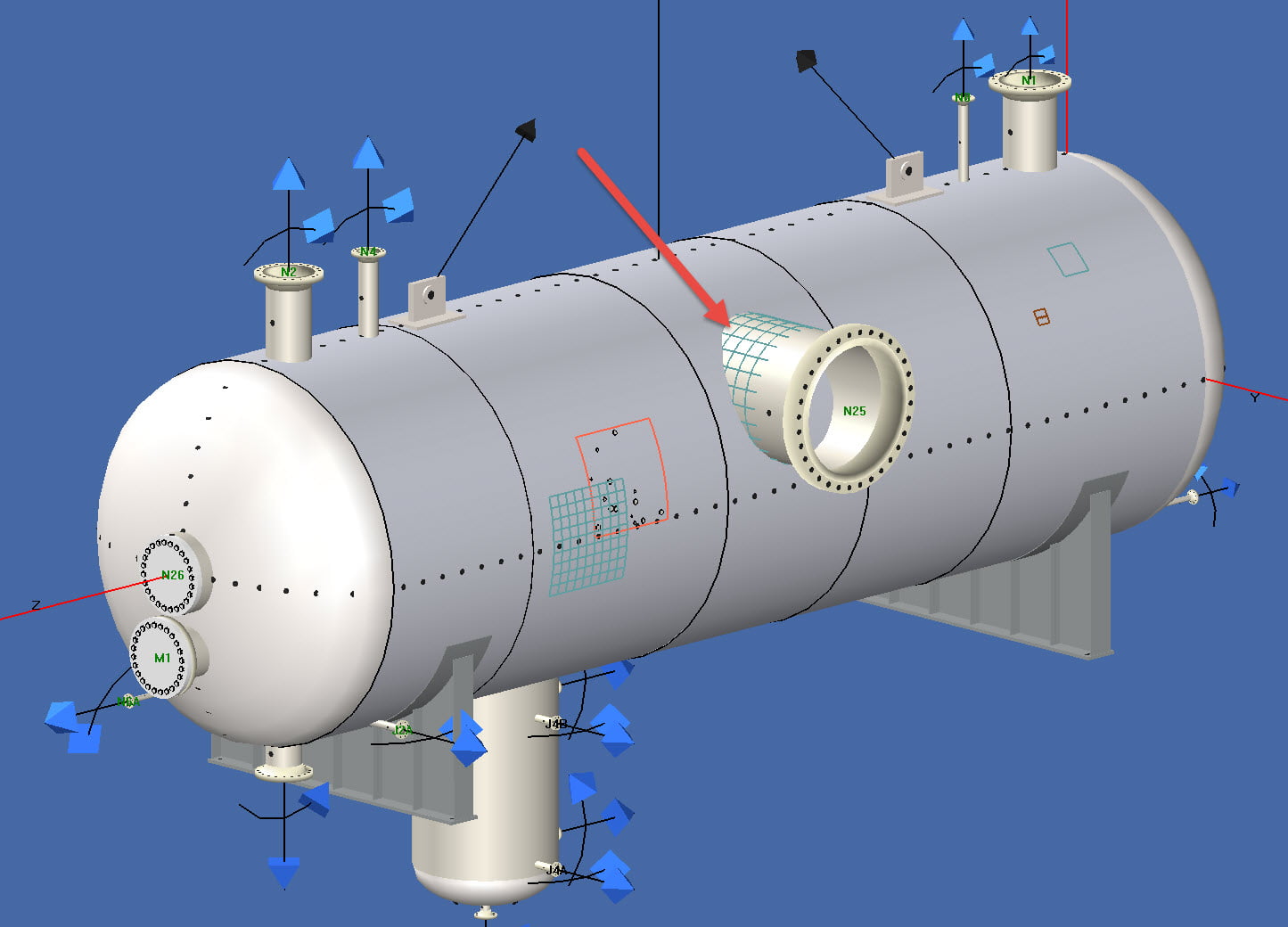

To conclude, FFS executes multidisciplinary engineering analysis that assures process and plant equipment such as pressure vessels, piping, and tanks operate efficiently and reliably, it also permits the operation of the damaged component safely for a particular period setting forth appropriate recommendations in terms of remedial actions.

Please contact us for more information and assistance.

2 Comments

Comments are closed.

Hi i am looking forward job opportunity in Dubai. If any please contect me on below mob no. 9925005095

Dear Shardul. Kindly check our careers page for current updates from time to time to see if there is any job openings that matches your interest.

https://velosiaims.com/careers/

Thanks!