Risk Based Inspection (RBI)

Risk-based Inspection sets forth a comprehensive approach towards the maintenance of business processes used to analyze various equipment. It is a decision-making technique to optimize inspection plans. Led by industry experts, we employ a comprehensive and structured approach – in line with industry guidelines following API 580, 581 and API 571 – to analyze the potential risks of each asset by evaluating their current operating conditions in terms of the probability and the consequence of failure, providing our clients with a unique view of the condition of each asset.

Strategic Inspections, Operational Excellence, Maximizing Efficiency

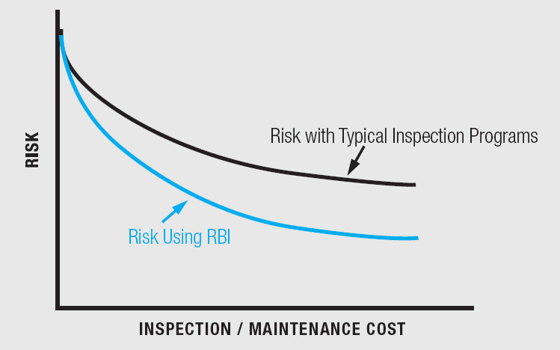

Elevate your asset management with Velosi’s Risk-Based Inspection (RBI) service, which is set to precisely formulate accuracy and efficiency. Our proactive approach empowers organizations to strategically prioritize inspections, focusing on potential failure risks. This risk-centric approach allows for the creation of inspection plans that optimize resource allocation.

Read More

Benefits of RBI

Identify the high-risk values

Understand the risk drivers and develop mitigation plans.

Generate focused inspection plans which enhance safety and reduces risk.

Assist to improve asset reliability.

Increase confidence in equipment integrity and reliability

Maximizes resource utilization.

Enhance operating efficiency.

Develop a cost-efficient approach.

RBI Deliverables

Corrosion Loop Drawings

Inspection Isometric Drawings for Equipment and Piping

Inventory Group Drawings

Inspection Isometric Drawings for Equipment and piping

Technical Risk Based Inspection (RBI) Report

Corrosion and Inspection Strategy Document

Integrity Operating Window

Asset Passports

RBI Case Studies

RBI Insights

-

Risk Based Inspection (RBI) & Corrosion Control Document (CCD) for SACE Project (Saudi Arabia Jafurah Utilities, Sulfur and Interconnecting Systems)

Hyundai Engineering & Construction Co., Ltd.

Korea

2024

-

Risk-Based Inspection (RBI) Assessment and Corrosion Management Program (CMP) for WRDD Plants

Saudi Aramco

Saudi Arabia

2021

-

Risk Based Inspection (RBI)for Corrosion Management Program (CMP) Finalization

SK Engineering and Construction

South Korea

-

RBI Study for CMP SNGL

Saudi Aramco

Saudi Arabia