Bowtie Analysis – An Extensive HSE Tool

- January 19, 2024

- Posted by: Velosi Author

- Categories: HSE, Insights

Bowtie Analysis is one powerful tool in Health, Safety, and Environment (HSE). It is a major part of the safety and risk studies.

What is Bowtie Analysis?

The Bowtie Analysis is a simple process for identifying where new or enhanced controls may be worthwhile. It is a core part of risk treatment planning, particularly where there is a high level of risk or where control effectiveness is assessed as low.

The benefits of bowtie analysis include:

- The ability to highlight vulnerabilities

- Model scenarios

- Evaluate existing controls and risk management measures

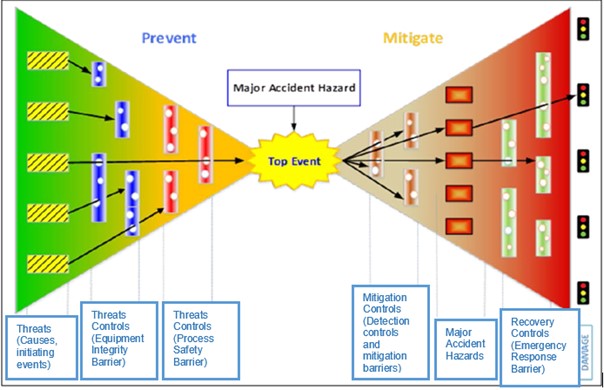

Moreover, a Bowtie Analysis uses a knot to show a dangerous event, like an accident, and two wings to represent the things that can cause or be caused by the event.

In simpler terms, it is a breakdown of a project showcasing its effects. One side shows why something bad might happen and the other side shows what could happen as a result.

Identifying Threats

In the first step of Bowtie Analysis, we identify possible threats or reasons that could cause a dangerous situation, the issues that may lead to something disasters in any industry. These haphazard situations can be anything from machines not working properly to man-made mistakes. The issues may look small but can lead to different threats.

In a factory, a threat could be a machine not working properly or a worker not being safe. It needs to be tackled and once the bowtie analysis is successfully performed and the problem is identified, the experts do their best to resolve the issues.

Preventative Measures – Barriers

To stop these dangers from causing real accidents, we set up things to stop them, called barriers. Yes! Just to obstruct to save things from getting damaged. Barriers help to mitigate haphazard situations.

Understanding Consequences

Now, let’s talk about result consequence. Remember you must have a versatile setup that can tackle the result. However, consequences can include physical harm and damage to the environment, as well as to the budget.

In most cases, it leads to environmental damages such as fires or other chemical gas-related issues instead of leading to physical harm. Nevertheless, in most factory, a result could be a worker getting hurt because a machine stopped working properly. It generally gets identified pretty quickly using Bowtie analysis. Therefore, in professional industries, the probability of a worker getting hurt is quite low.

Benefits

| Prevention Benefits | Mitigation Benefits |

|

|

|

|

|

|

|

Conclusion – Continuous Improvement

Bowtie Analysis is a critical process that needs to always get better. With time, experts ensure the use of professional materials and ensure the safety of the products for the best results.

As advancements take place or the working conditions change, we need to update the analysis to make sure it still works well in preventing accidents and reducing their impact. It leads to a more secure and efficient working environment that enhances the overall productivity of the employees working in that specific industry.

Please contact us for more information and assistance.