Importance of Drilling Rig Inspection – HSE

- February 16, 2023

- Posted by: Velosi Author

- Categories: HSE, Insights

Introduction to Drilling Rig Inspection

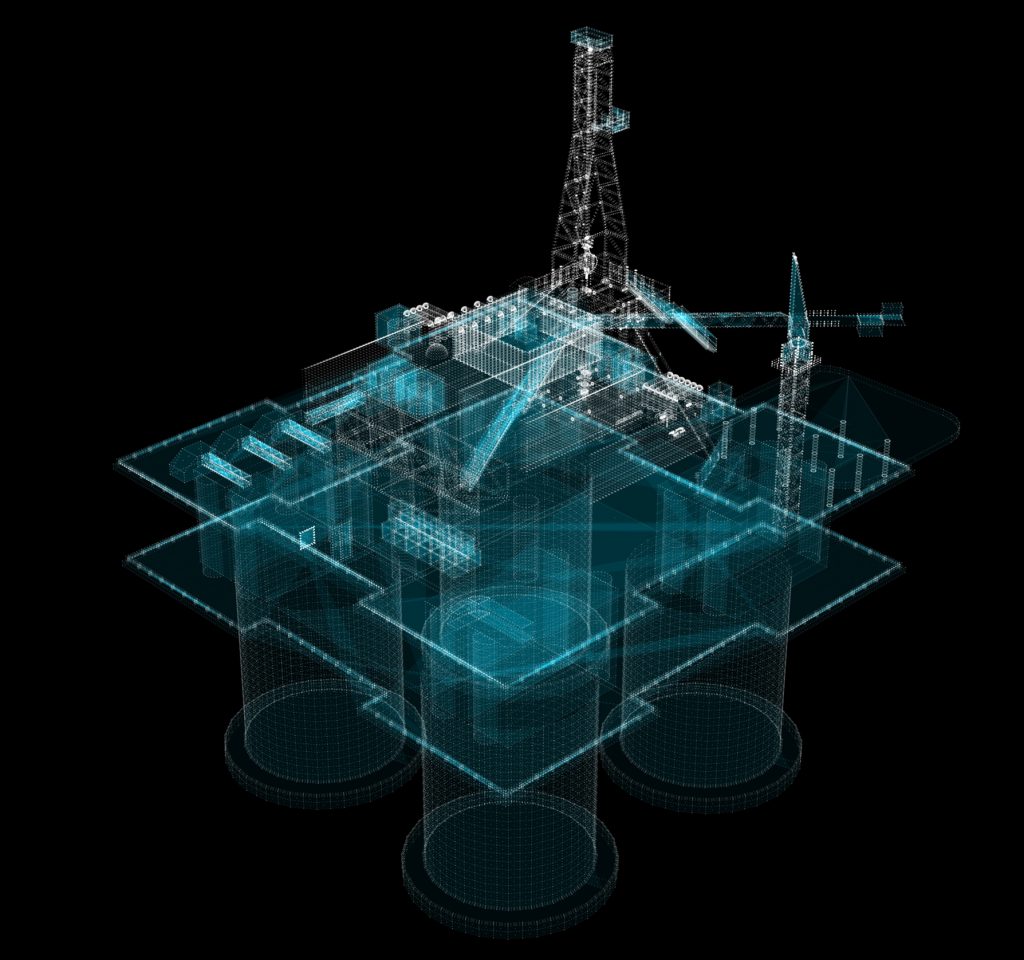

Drilling Rig Inspection is mandatory to ensure the safety of the asset and surrounding on site. A drilling rig is an integrated unit of machinery and infrastructure used for the exploration, drilling, and extraction of oil. In order to ensure efficient and secure operations, these rigs can be located both onshore and offshore, requiring daily management and detailed oversight.

Furthermore, during the installation phase, these drilling rigs are subjected to critical inspections for regulating systematic operations, which involve acceptance pressure, and rig floor testing following other mandatory audits.

Key Features of Drilling Rig Inspection

Rigs play an important role onshore and offshore to carry out critical operations and processes in the Oil and Gas and Petrochemical industries. The foremost purpose of drilling rig inspections is to critically assess the condition of the drilling assets prior to the installation phase. Additionally, compliance with specified industry standards, such as API is mandatory. To note, all rig inspections are conducted according to client requirements.

Moreover, rig inspections are critical components of HSE management, as they assist to identify potential hazards associated with drilling operations and ensure the safety of surrounding personnel and the environment. To execute accurate results, these inspections require regular checks on equipment, processes, and personnel, which are conducted through relevant inspection checklists.

Essentials of Rig Inspection Checklist:

- Pressure Testing

- Rig Floor Testing

- Equipment compliance with API and OSHA

- Rig Safety Management Protocols

- Testing with Effective Management Systems

- HSE Specified Procedures

- Execution of Proper Safety Plans

A systematic approach to the rig inspection checklist can significantly reduce the likelihood of unwanted incidents.

10 Leading Benefits of Drilling Rig Inspection

- Enhancing rig efficiency and reliability.

- Identifying hazards prior to the commissioning phase.

- Carefully examining potential risks.

- Assuring a safe and secure working environment.

- Reducing equipment overhead maintenance costs.

- Improving overall asset/equipment productivity.

- Minimizing adverse environmental impact on the surroundings and personnel.

- Following ‘Fit for Purpose’ approach towards the condition of the equipment.

- Allows collaborative working with a team of operators and drilling contractors.

- Enables effective judgment during the inspection phase for regulating safety.

Significance of HSE in the Oil and Gas Industry

The oil and gas industry is a critical component of the global economy but potentially intends to be a hazardous industry that poses risks to workers and the environment. Therefore, the implementation of Health, Safety, and Environment (HSE) protocols shall be of utmost priority.

HSE incorporates a set of measures, policies, and procedures planned and executed to ensure safety. Moreover, to ensure proper implementation of HSE protocols, companies in the oil and gas industry must have a comprehensive HSE management system in place, which should include a clear framework for identifying, evaluating, and assessing risks, as well as procedures for implementing and monitoring HSE policies regularly.

Precisely, organizations shall prioritize the proper implementation of extensive HSE management systems and protocols, which will have a productive impact on the economic and social aspects of the industry.

Velosi’s Drilling HSE Consultancy Services

Velosi offers extensive expertise in the HSE sector. Our drilling rig inspection services focus on applying effective management systems and best practices to support the management systems of your facility throughout the entire production life cycle thus, ensuring safety.

Please contact us for more information and assistance.