- May 29, 2025

- Posted by: Velosi Author

- Categories: Asset Integrity, Insights

Risk Based Inspection (RBI) is a systematic methodology that optimizes inspection-related procedures and ensures integrity management of different pressure systems through precise and effective risk analysis.

RBI is predominantly based on risk assessment, which follows risk identification, safe operating windows, corrosion, and inspection strategies for specific process equipment. Efficient risk-based inspection promotes strategic inspections and operational excellence with minimum overhead costs. For example, analyzing static equipment through qualitative or quantitative assessment of the probability of failure (PoF) and the consequence of failure (CoF).

Risk Based Inspection Methodology

RBI utilizes a precise yet analytical methodology. It begins with a collection of accurate data of the asset/equipment following inspections based on potential damage and malfunctions due to various reasons, which can be based on several frequency rates.

The collected data can then be inspected based on the following core RBI approach:

- Qualitative: This involves descriptive data based on expertise and judgments by using checklists and pre-defined categories. It is mostly the best approach for instant decision-making scenarios.

- Quantitative: This approach includes precise statistics and probability rates, which ensures accurate data with cost-benefit analysis.

- Semi-Quantitative: Systematically combines both qualitative and quantitative approaches, focusing on accurate qualitative methods, and is less complex than full quantitative methods.

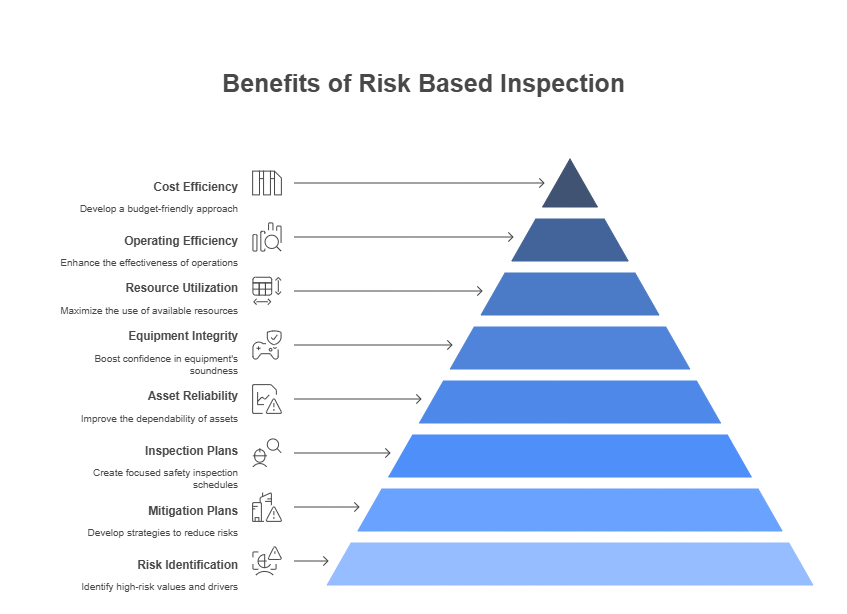

Benefits of RBI

- Risk Identification: Identifies the high-risk values

- Mitigation Planning: Identifies risk drivers and develops effective mitigation plans.

- Inspection Plans: Generates focused inspection plans that enhance safety and reduce risk.

- Asset Reliability: Assists in improving asset reliability.

- Equipment Integrity: Increases confidence in equipment integrity and reliability

- Resource Utilization: Maximizes resource utilization.

- Operational Efficiency: Enhances operating efficiency.

- Cost Efficiency: Develops a cost-efficient approach.

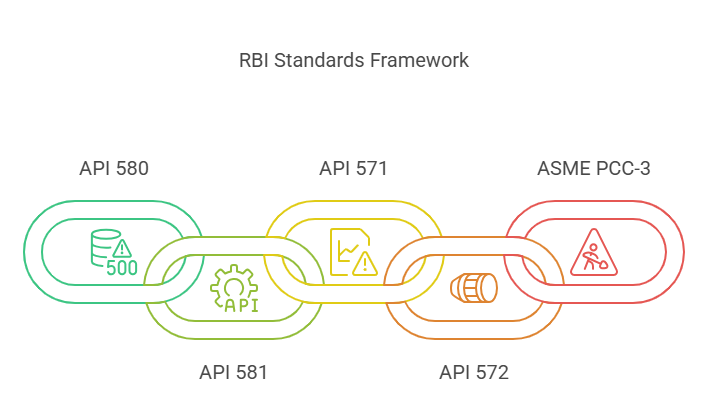

RBI Standards: What You Need to Know

To ensure compliance and effectiveness, RBI programs in the oil and gas industry should align with globally recognized standards:

- API 580 – Risk-Based Inspection

Provides a framework for developing and implementing RBI programs.

- API 581 – RBI Technology

Offers detailed quantitative methods for calculating PoF (Probability of Failure) and CoF (Consequence of Failure).

- API 571 – Damage Mechanism

Provides comprehensive details and analysis of degradation mechanisms that affect process equipment.

- API 572 – Inspection of Pressure Vessels

Ensures thorough standardized inspections for high-risk pressure vessels.

- ASME PCC-3

Guidelines for inspection planning using risk-based methods.

How We Support Risk Based Inspection in The Oil and Gas Industries

Velosi’s Asset Operations Process is based on risk-based strategies for maintenance and inspection planning (i.e., time-based, condition-based, operational, or corrective maintenance). These strategies are aligned with company and plant objectives related to plant availability and safety. Risk-based methods, such as Reliability, Availability, and Maintainability (RAM), Reliability-Centered Maintenance (RCM), and Risk Based Inspection (RBI), can support ranking systems, equipment, and develop strategies for efficient maintenance and inspection.

At Velosi Asset Integrity Limited, we provide comprehensive Risk-Based Inspection services tailored for the oil and gas sector. From upstream platforms to downstream processing plants, our RBI expertise helps clients with:

- Developing RBI frameworks based on API 580 & 58.

- Minimizing lost production and downtime through building cost cost-effective inspection program without compromising safety and the environment.

- Implementing RBI software solutions integrated with CMMS or EAM systems.

- Performing corrosion assessments and failure mode evaluations.

- Optimizing inspection schedules using semi-quantitative and quantitative methods.

- Ensuring compliance with international inspection and integrity standards.

Our team of certified RBI engineers and inspection specialists deploys advanced tools and real-world experience to minimize risk and maximize operational uptime.

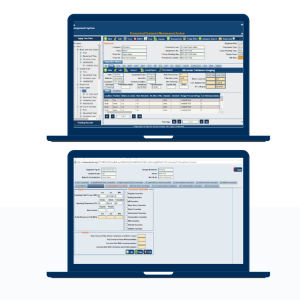

VAIL-Plant®: The RBI Powerhouse for Onshore & Offshore Integrity

At Velosi, we utilize VAIL-Plant®, Velosi’s custom-built software solution, to deliver advanced Risk-Based Inspection services across both onshore and offshore oil and gas facilities.

What is VAIL-Plant®?

VAIL-Plant® is an industry-leading custom-built Plant Integrity Management Software used by major oil & gas companies to centralize, track, and optimize asset inspection, maintenance, and integrity processes.

PIMS: Pipeline Integrity Management System

The PIMS module within VAIL-Plant® supports RBI by facilitating:

- Centralized database for all static equipment

- Risk ranking based on API 580/581 methodologies

- Corrosion loop mapping & degradation mechanism assignment

- Integration with NDT results and thickness monitoring

- Customizable inspection strategies for onshore and offshore environments

PIMS Onshore & Offshore Module Key Features:

- Pipeline profile recording and plotting

- Probability of Failure (PoF) calculation and plotting against the applicable damage mechanism.

- Consequence of Failure (CoF) calculation against the applicable damage mechanism.

Risk assessment against third-party damages - Risk assessment against stress corrosion cracking (SCC)

- External and internal corrosion direct assessment (ECDA & ICDA)

- Corrosion calculation (NORSOK M-506)

- Scheduling of integrity management and inspection

- Defect assessment based on B31.G, modified B31.G, and Shell 92.

- Graphical trends and drawings management

- Precise and effective reporting

For Onshore Facilities – PIMSON

- Manages pressure vessels, piping, heat exchangers, and tanks

- Custom RBI dashboards to track risk across facilities

- Enables condition-based inspections aligned with site-specific risks

Click here for more information

For Offshore Installations – PIMSOFF

- Tracks structural integrity of risers, subsea components, and topside equipment

- Considers unique offshore hazards like fatigue, marine corrosion, and wave loading

- Facilitates synchronized offshore shutdown planning via RBI insights

Click here for more information

PEMS: Pressurized Equipment Management System

PEMS is a specialized module within VAIL-Plant® for managing pressure-retaining equipment.

It supports RBI with:

- Capturing detailed inspection histories

- Calculating remaining life and retirement thickness

- Performing fitness-for-service (FFS) assessments

- Identifying potential failure modes across pressure systems

- Generating RBI-based inspection intervals and scope

- Short/long-term corrosion rate calculations

- Plant inspection requirements (PIR’s generation)

- Root cause analysis (RCA) against failures

- Time, cost, and resource (CRR) management

- Graphical trends and drawings management

- Precise and effective reporting

- Custom query

With PEMS, it is easier to identify high-risk assets and optimize inspection frequencies, ensuring both compliance and cost-efficiency.

SIMS: Structural Integrity Management System

SIMS is a specialized module within VAIL-Plant® custom-built based on international codes, such as ISO 19900, ISO 19902, ISO 19904, and API RP 2 SIM to ensure the sustainability and integrity of onshore and offshore structures during all the phases of the structural life cycle.

It supports RBI with:

- Integrity management dashboards

- Identification of failure modes

- RBI Assessment

- Failure modes and effects analysis (FMEA)

- Risk evaluation and maintenance

- Inspection planning and risk management

- Determination of PoF & CoF

- Inspection history recording

- Graphical trends and drawing management

- Precise and effective reporting

- Custom query

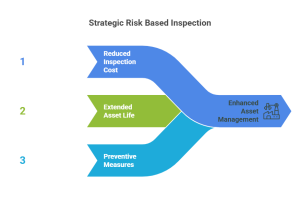

Risk Based Inspection at Velosi Emphasizes

- Reduced inspection cost without compromising safety

- Extend asset life cycle through proactive degradation management

- Preventive measures towards major potential failures

Our Risk Based Inspection Case Studies

Velosi, with decades of experience, has worked on several risk based inspection projects to efficiently maintain and optimize asset integrity for leading organizations.

Click here for RBI Case Studies

Prioritize strategic risk based inspections for your facility with Velosi!

Enquire now:

Stay connected for more blogs!

Please contact us for more information and assistance.