Significance of Quality Performance Standards In HSECES

- November 17, 2023

- Posted by: Velosi Author

- Categories: HSE, Insights

Introduction

Health, Safety, Environment Critical Equipment and Systems (HSECES) play a pivotal role in preventing and managing major accidents. The selection, design, and maintenance of HSECES are prioritized to the highest degree. Process Safety Management (PSM) revolves around recognizing, averting, managing, and alleviating the inadvertent release of hazardous materials or the loss of primary containment that could lead to severe incidents like fires, explosions, mass injuries, or fatalities.

The management of HSECES encompasses ongoing efforts in maintenance, inspection, testing, and maintaining a comprehensive performance history to uphold their operational integrity. Continuous monitoring is essential for ensuring that HSECES adhere to established standards and remain in optimal working conditions. This diligent monitoring contributes to the consistent adherence to safety protocols and the sustained maintenance of HSECES in their designated and effective operational states.

What are the Performance Standards?

A Performance Standard serves as an expression, articulated in qualitative or quantitative terms, outlining the expected performance of a system or equipment component. It forms the foundation for ensuring and validating the integrity of Health, Safety, Environment Critical Equipment and Systems (HSECES) throughout the entirety of the installation’s lifecycle. These standards are dynamic documents, continuously evolving, and delineate the essential baseline performance criteria for HSECES in both regular and emergency scenarios, specifically in the context of managing major accidents.

Quality performance standards for HSECES

Performance standards serve as the groundwork for defining the anticipated performance of Health, Safety, Environment Critical Equipment and System (HSECES). Consequently, it is crucial to establish and specify these standards for identified Health, Safety, Environment Critical Equipment and System (HSECES) during the design phase, with periodic updates throughout the operational stage. Unfortunately, there is a recurring issue where considerable effort is invested in creating Performance/Verification Standards, only to have the process appear as an end in itself. This can be attributed, in part, to the complex nature of Performance Standards and the inadequate connection between these standards and their associated verification requirements. It becomes challenging to ascertain if Health, Safety, Environment Critical Equipment and System (HSECES) has been compromised when there is ambiguity about its intended function. This underscores the importance of having QUALITY Performance Standards that provide clarity on the role each HSECES must fulfill.

What are the Key Elements of Performance Standards in HSECES?

Once the HSECES has been identified it is paramount to define its function in terms of a Performance Standard. These are like criteria that one needs to define, based on which we can measure the performance of HSECES. The performance standards are defined based on:

- Overall Goal;

- Boundary/ Equipment components within the HSECES system;

- Requirements in terms of Functionality/ Reliability/ Availability/ Survivability

- Dependencies/ Interactions in order to ensure the performance goals of the HSECES are met and

- References as design documentation or codes/ standards.

HSECES and performance standards are input to the Safety register or operation safety case. In accordance with the Performance Standard, tasks of assurance can be established within the maintenance system to guarantee the achievement of the desired performance. During operation analyzing the data in the maintenance, the system guarantees that all the HSECESs required to manage Major Accidents are functioning correctly. If there are any differences from the agreed performance standards, corrective actions are taken to restore the system’s integrity.

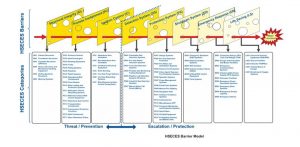

The HSECES Barrier cheese Model is shown to represent the HSECES Barrier and categories for easy understanding.

Barrier Diagram Cheese Model:

What is the Best Way to Measure Quality Performance In HSECES?

- Risk Assessment:

Verify that a thorough risk assessment has been conducted to identify potential hazards and risks associated with HSECES. The performance standards should address the mitigation of these risks.

- Stakeholder Input:

Confirm that stakeholders, including engineering experts, safety professionals, and end-users, have been involved in the development process. Their input ensures that the standards reflect a comprehensive understanding of the HSECES’ requirements.

- Clear and Measurable Criteria:

Check that the performance standards are clear, specific, and measurable. Each criterion should be defined in a way that allows for objective assessment and quantifiable measurement.

- Performance Indicators:

Ensure that performance indicators are established to monitor and measure the effectiveness of HSECES.

- Reliability Requirements:

Verify that the standards include reliability requirements for HSECES. This may involve specifying parameters such as failure rates, mean time between failures (MTBF), and other reliability metrics.

- Comprehensive Documentation:

Check for comprehensive documentation of the performance standards. Documentation should cover design specifications, testing procedures, maintenance requirements, and any changes made over time. Well-documented standards contribute to transparency and accountability.

- Testing and Validation Procedures:

Confirm that testing and validation procedures are defined within the standards. This includes protocols for assessing the performance of HSECES under various conditions, including normal operation and emergency scenarios.

- External Validation:

Consider engaging an Independent Verification Body (IVB) or Independent Competent Person (ICP) to validate the developed performance standards. External validation provides an independent assessment and can offer valuable insights.

- Clear Communication:

Confirm that the developed performance standards are communicated clearly to all relevant stakeholders. This includes operators, maintenance personnel, management, and regulatory authorities.

Conclusion

To conclude, the importance of Quality Performance Standards in HSECES is critical for protecting both the workforce and the environment from severe hazards such as fires, explosions, and the release of harmful gases or vapors. These performance standards guarantee that adequate inspection, maintenance, and testing are thoroughly conducted according to specific Preventive Maintenance Standards. Therefore, the value of Quality Performance Standards in HSECES is rooted in their capacity to encourage a safer and more secure work environment.

Please contact us for more information and assistance.