- May 12, 2025

- Posted by: Velosi Author

- Categories: Asset Integrity, Insights

Introduction: Why Refineries Need Smarter Risk-Based Inspection

Refineries are complex, high-risk facilities that require strict adherence to regulatory standards. A strategic change from time-based inspections to Risk-Based Inspection (RBI) becomes essential for maintaining mechanical integrity and reducing failures while extending inspection periods.

Refineries’ risk based inspection serves dual purposes of safety resource allocation and failure mechanism by understanding asset lifecycle strategy alignment. Velosi’s VAIL-Plant® follows the RBI process and delivers a powerful risk-based inspection solution for refinery operations that combines digital functionality with standards compliance and technical strength.

Understanding RBI in the Context of Refineries

Risk-Based Inspection applies a quantitative and qualitative approach to determine:

- Probability of Failure (PoF) based on degradation mechanisms like corrosion, creep, HIC/SOHIC, stress corrosion cracking, and fatigue.

- Consequences of Failure (CoF) include impact on safety, environment, production loss, and reputation.

For refineries, typical equipment subjected to RBI includes:

- Pressure vessels

- Heat exchangers

- Storage tanks (API 653)

- Piping circuits (API 570)

- Fired heaters

- Reactors and columns

Technical Challenges in Manual RBI Programs

Despite RBI’s value, manual implementations are prone to:

- Inaccurate risk categorization due to inconsistent data.

- Delayed updates in corrosion rates and damage mechanisms.

- Difficulty integrating inspection results with maintenance plans.

- High potential for human error in risk matrix evaluations.

How VAIL-Plant® Technically Powers Refineries ‘ Risk-Based Inspection

VAIL-Plant® by Velosi is engineered to deliver a fully automated and technically accurate RBI ecosystem. Here’s how it enables refineries to elevate their inspection and integrity strategies:

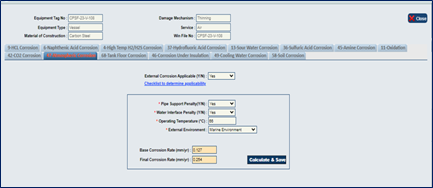

- Degradation Mechanism Mapping

- Automatic linkage of damage mechanisms with equipment types and process conditions.

- Supports all major degradation modes per API 581, including internal/external corrosion.

- Considers factors like temperature, pressure, fluid composition, and inspection history.

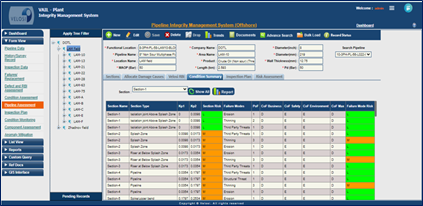

- Risk Calculation Engine (API 581 Compliant)

- Calculates PoF and CoF using built-in RBI logic.

- Generates risk ranking (Low/Medium/High/Very High) for each asset/component.

- Supports both Level 1 (qualitative) and Level 2 (semi-quantitative) RBI assessments.

- Allows sensitivity analysis by modifying variables like inspection effectiveness or corrosion rate.

- Corrosion Loop Management

- Segregates piping systems into corrosion loops with uniform degradation profiles.

- Tracks actual vs. predicted corrosion rates.

- Enables risk aggregation and area-based inspection optimization.

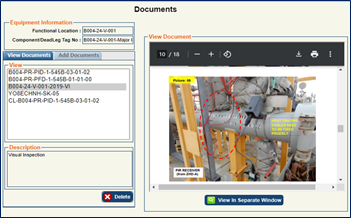

- Inspection Data Integration

- Binds NDT results, thickness readings, visual inspections, and repair history to RBI logic.

- Visual indicators alert for overdue inspections or deviation from expected degradation.

- Accepts input from UT, RT, MT, PT, and advanced inspection techniques.

- Smart Inspection Planning and Scheduling

- Auto-generates inspection plans based on risk priority.

- Considers Remaining Life, Inspection Effectiveness, and T-min alerts.

- Integrity Operating Windows (IOWs)

- Custom configuration of IOWs to monitor critical process parameters (e.g., flow rate, pressure, temperature).

- Alerts when operational data trends toward limits that could accelerate degradation.

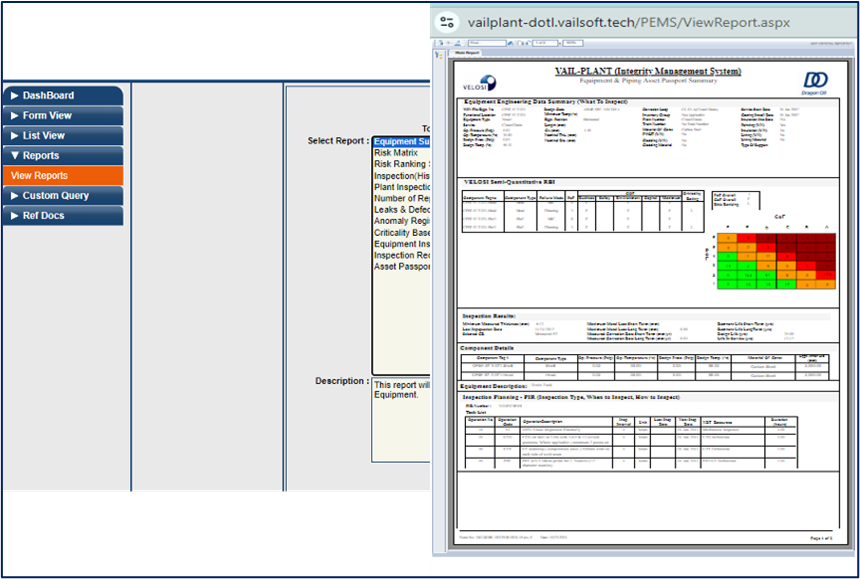

- Predictive Analytics and Reporting

- Predictive Analysis of Failure Likelihood

- Auto-generated reports including:

- Risk summaries

- Equipment condition ratings

- Inspection effectiveness logs

- Compliance dashboards

- Audit and Compliance Reporting

- Real-time dashboards for auditors and regulators.

- Traceable inspection records aligned with API 580/581, OSHA PSM, and ISO 55001.

- Full version control and audit trails for every risk analysis and plan.

Key Technical Benefits for Refineries Risk Based Inspection

| Features | Technical Advantages |

| Risk Model Customization | Modify PoF/CoF equations to fit refinery-specific standards. |

| Corrosion Loop Intelligence | Define and reassign loops based on operational or material changes. |

| Dynamic Risk Matrix | Adjust severity/consequence parameters based on real-time process shifts. |

| IOW Monitoring | Prevent degradation through early warning thresholds tied to process historians. |

| Multi-Standard Compliance | Built-in frameworks for API 580/581, API 570, API 510, API 653, ISO 14224. |

Conclusion: Smarter Future with VAIL-Plant®

To conclude, as refineries face growing complexity, regulatory oversight, and economic pressure, RBI must evolve beyond spreadsheets and legacy tools. VAIL-Plant®, following the RBI process, empowers engineering teams with a scientifically grounded, digitally intelligent, and fully compliant risk-based inspection platform tailored for refinery operations.

With real-time risk visibility, predictive planning, and full lifecycle asset tracking.

VAIL-Plant® doesn’t just support RBI, it transforms it.

Digitize your refinery’s RBI strategy- Start with VAIL-Plant®.

Stay connected for more blogs!

Please contact us for more information and assistance.