- July 22, 2025

- Posted by: Velosi Author

- Categories: Engineering, Insights

Introduction

The energy sector demands advanced oilfield engineering services that deliver safety and sustainability at an unprecedented level in the fast-paced industry. Oil and gas industry operators must overcome three major obstacles, including production optimization, risk reduction, and environmental standard compliance.

Velosi, a worldwide trusted leader, provides comprehensive oilfield engineering services tailored to the specific operational requirements of your organization. Velosi delivers asset performance optimization through decades of experience, combined with cutting-edge technology and a commitment to quality, to empower energy companies.

About Velosi: Your Strategic Engineering Partner

Velosi combines engineering expertise from multiple disciplines with industry-leading technological capabilities. Our approach follows global standards (ISO, API, ASME), but we adapt them to match regional operational needs. The result? Solutions that are as effective in execution as they are in design. Our engineering teams focus on delivering high-quality, cost-effective solutions that enhance operational excellence in onshore and offshore fields.

From early-stage design to lifecycle asset management, we offer oilfield engineering services designed to minimize risk, maximize uptime, and meet the evolving demands of energy infrastructure.

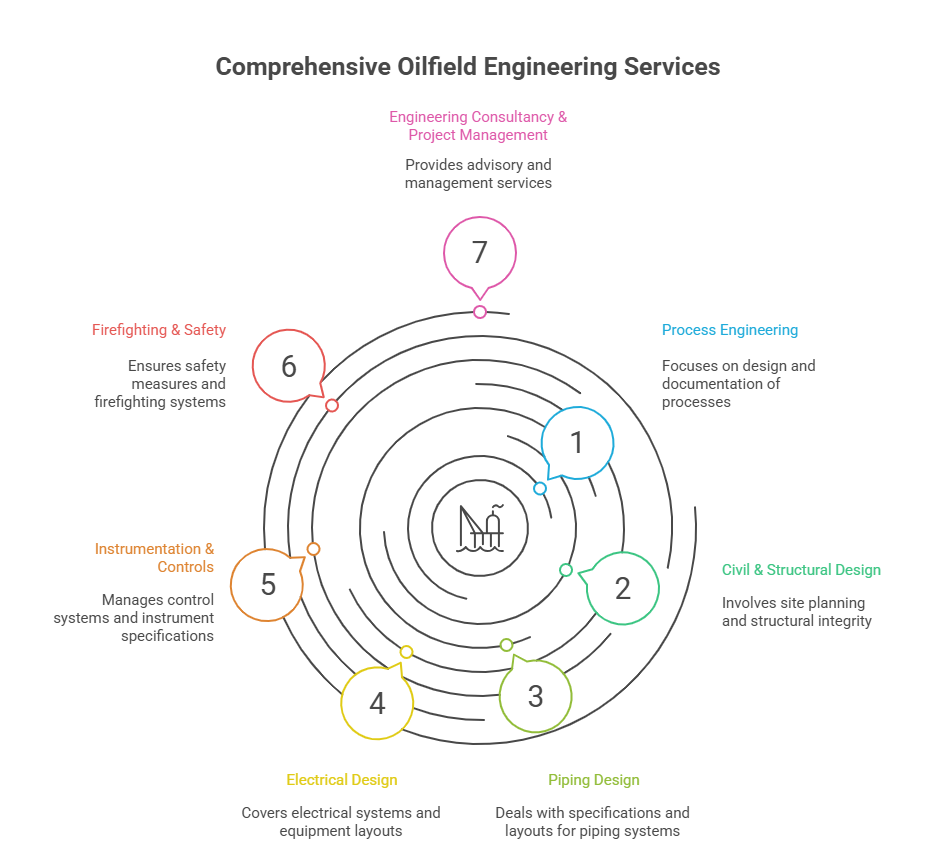

Velosi’s Core Oilfield Engineering Services

- Process Engineering

- Conceptual Design, FEED, and Detailed Design

- Process Flow Diagrams (PFDs)

- Utility Flow Diagrams (UFDs) and Heat & Material Balances

- Process Simulation Report & Process Design Calculations

- Piping & Instrumentation Diagrams (P&IDs)

- Cause & Effect Diagrams

- Process & Operational Control Description

- Data Sheets

- Pre-commissioning and Commissioning Manual

- Operating & Maintenance Manual

- Civil & Structural Design

- Civil Design Criteria

- Overall Site Plot Plan & Civil Layouts

- Structural Design Criteria & Structural Drawings/Schedules

- Foundation and Concrete Structure RC Details

- Underground Services Specification, Layout & Design Details

- Paving Plan and Details Drawings

- Road Layouts and Details

- Piping Design

- Piping Material Specifications

- Heat Tracing/Jacketing Specification

- Piping General Arrangement Drawing & Isometric Drawings

- Material Take-offs

- Key Plans

- Stress Analysis

- Pipe Supports Design Details & Special Pipe Support Register

- Pipe Support Spring Register and Calculations

- Electrical Design

- Area Plans & Layout Drawings

- Single-Line Diagrams (interlocks, inter-tripping, capacity, voltage, current, impedance, generation power)

- Schematics & Equipment Drawings (Transformers, Switchgears, MCCs, UPS, Chargers, Generators, Power Supplies, PTs, CTs, Control Panels, etc.)

- Inter-connection Diagrams

- Cable Trench Layouts & Power Distribution Schedule

- Instrumentation & Controls

- System Block Diagrams

- Instrument Specifications (equipment & materials)

- Instrument Index & Relief/Safety Device Index

- Alarm & Trip Schedule

- Control Room & Control Building Layouts

- Instrument Cable Routing & Power/Utility Requirements

- Loop Diagrams & Input/Output Schedules

- Instrument Junction Box Schedules

- Firefighting & Safety

- P&ID for Fire-Water Ring Main

- Firefighting Equipment List / Requisition

- Fire & Gas Detection Equipment Schedule

- Safety Equipment Schedule

- Fixed Extinguishing Systems Design (foam, CO₂, clean agent, dry powder)

- Mobile Firefighting Equipment

- Engineering Consultancy & Project Management

- Advice & supervision from the earliest stages to start-up

- Project management teams (project controls & engineering)

- Direct client assistance in project definition & pre-feasibility

- Satellite teams to supervise design in contractor offices

- Pre-FEED & FEED engineering, tender production & bid evaluation

- Planning, schedule & logistics management

- Risk management

- FEED supervision & review

- Construction supervision & management

- Design & EPC tender evaluation, contract prep & negotiation assistance

- QA/QC, inspection & safety management with contractors

- Commissioning, training & handover

Oilfield engineering services at Velosi provide an expansive range of specialties, including mechanical, civil, structural, process, electrical, and instrumentation engineering. These services support every phase of an asset’s lifecycle.

Velosi offers an integrated approach that ensures seamless coordination across disciplines, improving efficiency and reducing operational risk.

Oilfield Engineering Services Explained: Process, Civil, Piping, Electrical, Control & Safety

- Process Engineering:

Transforms reservoir fluids into safe, saleable products by creating process flow diagrams, simulations, and control narratives that set every heat exchanger, separator, and relief valve in the field.

- Civil & Structural Design:

Provides wells and facilities with a strong base of laying out plots, foundations, and blast-resistant structures that survive storms, earthquakes, and heavy topside loads throughout the field’s lifecycle.

- Piping Design:

Builds the core functionality within the field, routing hydrocarbons, chemicals, and utilities through stress-analyzed pipes, supports, and heat-traced lines that keep production flowing efficiently.

- Electrical Design:

Powers the entire operation with safe, reliable electricity, designing generators, switchgear, and cabling that meet hazardous-area rules and deliver uninterrupted energy for pumps, compressors, and control systems.

- Instrumentation & Controls:

Provides functionality control within the field, specifying instruments, alarms, and control loops that automate production, detect leaks, and shut-in wells before incidents escalate.

- Firefighting & Safety:

Safeguards people and plant with engineered fire-water networks, suppression systems, and gas-detection layouts that comply with API and NFPA standards and guarantee rapid response to any emergency.

- Engineering Consultancy & Project Management:

Guides the entire journey, from pre-FEED optioneering to start-up by coordinating schedules, risks, and contracts for every engineering discipline. Delivers on time, on cost-efficient budget, and execution ready documents.

Engineering Twin in VAIL-Plant®

Engineering intelligence, not intuition, leads tomorrow’s oilfield. VAIL-Plant® turns every drawing into a living, decision-grade digital twin concept (API 580 and ASME B31.8S certified) of every pipe, vessel, cable, and instrument that exists in your oilfield asset. From the moment the first FEED sketch is issued, VAIL-Plant® imports PFDs, P&IDs, 3-D models, and data sheets, keeping them viable. Any change to valve size, pipe spec, or electrical load automatically reflects across all disciplines and life-cycle phases.

How it works

- Central hub – RBI, RCM, SIL, and FMECA modules feed real-time inspection, maintenance, and performance data back into the twin.

- Predict & optimize – Analytics forecast wall-loss, vibration, or compressor fouling weeks in advance, letting engineers run “what-if” debottleneck scenarios digitally.

- End-to-end traceability – Design revisions, construction red-lines, and post-start-up laser scans are time-stamped and linked, turning the same model that guided design into the single source of truth for revamps, tie-ins, and life-extension projects.

VAIL-Plant’s engineering twin bridges design intent with operational reality, ensuring your oilfield engineering services stay accurate, compliant, and future-ready from the very first to final decommissioning.

Digital Engineering & Asset Integrity with VAIL-Plant®

Velosi enhances its engineering services through VAIL-Plant® software, which combines asset integrity and performance management capabilities into a centralized solution. The real-time asset health monitoring capabilities of VAIL-Plant® help you track risk-based inspection metrics, asset condition monitoring, and lifecycle management. Asset performance monitoring and digital engineering support through VAIL-Plant® enables real-time data-driven decision-making and predictive maintenance. It sets forth real-time visibility into asset health, risk status, and performance trends, empowering you to:

- Monitor equipment health and structural integrity in real time.

- Prioritize maintenance and inspection activities based on risk and criticality

- Extend asset life and reduce unplanned downtime.

- Ensure compliance with international engineering codes and safety standards.

- Combine digital tools with traditional engineering workflows for proactive asset management and digital intelligence in engineering.

Why Choose Velosi for Oilfield Engineering Services?

- Proven Expertise: The company brings decades of experience in managing complex oilfield projects globally.

- Integrated Solutions: The company provides complete engineering solutions through its multi-disciplinary teams.

- Digital Innovation: Comprehends the utilization of VAIL-Plant®, digital twins, and advanced analytics.

- Safety & Compliance: The company maintains strict adherence to both industry standards and environmental regulations.

- Client-Centered Approach: Offers customized engineering solutions focused on your specific challenges and goals.

The Future of Energy: Sustainable Oilfield Engineering with Velosi

The global shift toward safer, more sustainable energy sources sets forth critical challenges and opportunities for oilfield engineering. At Velosi, we are committed to helping clients meet industry demands by integrating sustainability into every engineering project.

Our engineering teams design with an emphasis on:

- Low-emission and energy-efficient systems

- Water recycling and waste reduction solutions

- Cost-effective, sustainable strategies

- Digital technologies that enable predictive maintenance and reduce resource use, powered by VAIL-Plant®

Through this combination of engineering know-how and digital innovation, Velosi helps clients meet ESG targets while maintaining operational excellence. The future of oilfield engineering is not just about producing energy; it’s about producing it responsibly, efficiently, and sustainably.

Conclusion

The selection of appropriate oilfield engineering services determines the success of operations and engineering excellence. Velosi provides integrated, innovative, sustainable engineering services that help organizations construct safer, smarter, and more efficient oilfields that address future challenges and opportunities.

Achieve a sustainable energy future with Velosi!

Please contact us for more information and assistance.

Related Services

Asset Integrity Management with VAIL-Plant®

Risk Based Inspection (RBI) Solutions

Process Safety & Engineering Consultancy

Training & Certification Programs

Stay connected for more blogs!