- June 4, 2025

- Posted by: Velosi Author

- Categories: Engineering, Insights

The complex industrial landscape demands mechanical integrity as a critical element of asset performance, safety, and longevity. Whether you are managing a refinery, a high-pressure processing plant, or a multi-tiered offshore platform, the strength and soundness of your mechanical systems dictate your operational efficiency.

At Velosi Asset Integrity Limited, mechanical integrity is a comprehensive, data-driven strategy. Utilizing the core of that strategy, Velosi’s custom-built software solution, VAIL-Plant®, our cutting-edge asset integrity management platform, is built to help industries digitize, centralize, and optimize their mechanical integrity throughout the asset lifecycle.

What Is Mechanical Integrity and Why Does It Matter?

Mechanical integrity refers to the ability of critical mechanical equipment such as pressure vessels, piping systems, storage tanks, and structural supports to perform their intended functions without failure or degradation over time. The main objective of mechanical integrity is to prevent leaks, breakdowns, and catastrophic events that could lead to environmental disasters, financial loss, or worse, human injury.

For high-risk sectors like oil and gas, petrochemicals, and power generation, a proactive mechanical integrity strategy is more than a best practice; it’s mandated by global standards such as OSHA 1910.119, API 570, and ASME codes.

VAIL-Plant ®: Revolutionizing Mechanical Integrity Management

At Velosi, we have engineered VAIL-Plant not just as a digital solution but as a performance engine for industrial reliability. This intelligent, modular software system streamlines your mechanical integrity across every asset, every inspection, and every risk profile.

Let us break down the powerhouse modules behind VAIL-Plant that are tailor-made for mechanical integrity:

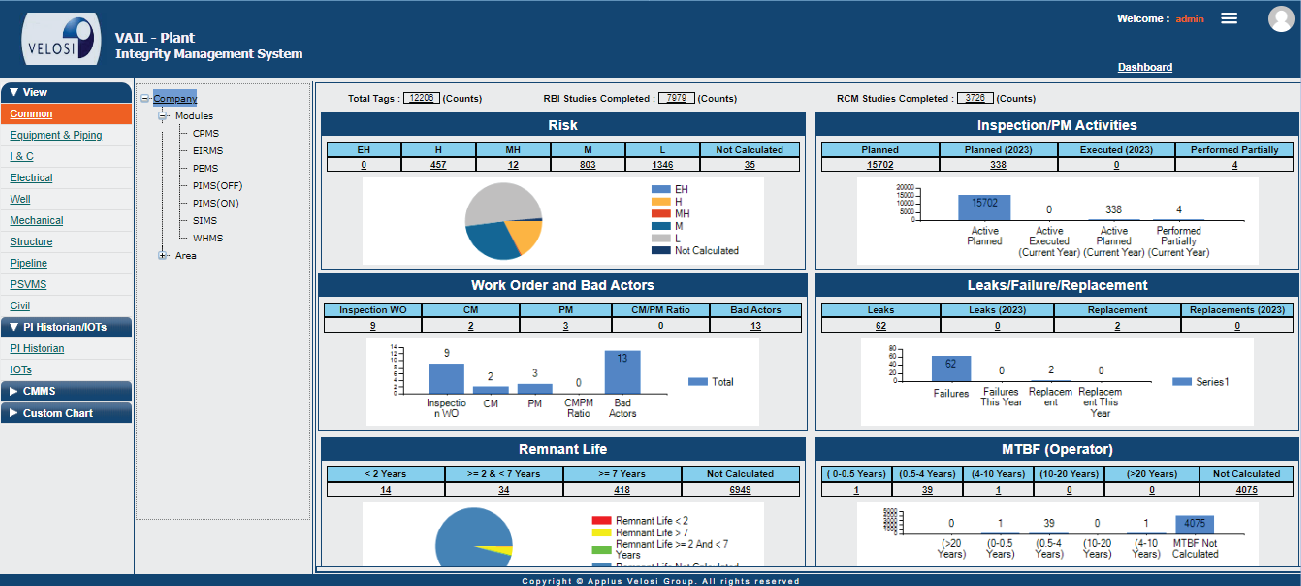

APMS is your command center for mechanical asset tracking and performance analysis. From pressure vessels and process piping to storage tanks, APMS creates a centralized database of asset health, inspection history, and maintenance strategies.

Key Features:

- Managing Risk-Based Inspection (RBI) workflows to prioritize inspection efforts.

- Relevant elements and key points of RBI, RCM, pipeline structures, which also include process information historian studies.

- Completed RBI and FMECA study results.

- Historical trending and anomaly detection.

- Predictive maintenance scheduling based on real-time performance indicators.

- Seamless integration with inspection data and engineering drawings.

APMS ensures your mechanical assets are not just surviving but performing at peak capacity. It helps turn inspection data into actionable intelligence.

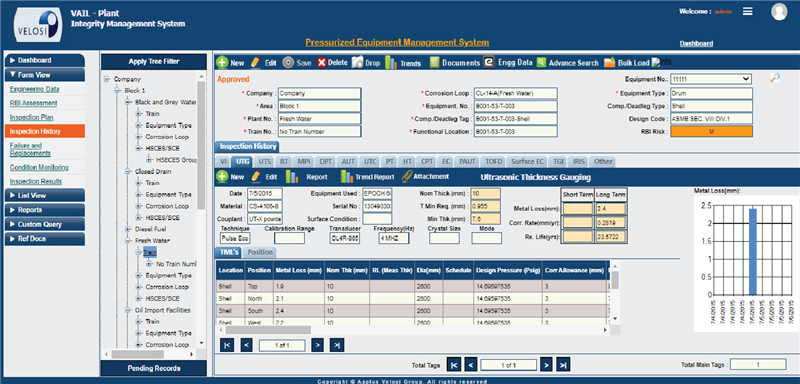

PEMS is specifically designed to manage the lifecycle integrity of pressure equipment such as boilers, pressure vessels, tanks, heat exchangers, and piping networks. It covers the complete risk assessment process, facilitates inspection planning, delivers full compliance with regulatory codes, and predicts asset remaining life and upcoming inspection dates. PEMS module overall also offers traceable documentation for audit-readiness.

Key Features:

- Code-compliant inspection planning (API 510, API 570, ASME).

- Estimated corrosion rate models based on API 581.

- Root cause analysis (RCA) against failures

- Analyses and overview of inspection components such as wall thickness monitoring, remaining life estimations, and corrosion rate calculations,

- Defect assessment based on B31.G, modified B31.G, and Shell 92.

- Failure and replacement history recording.

- Integrated repair and alteration tracking.

- Real-time alert systems for overdue or critical components.

PEMS reduces unplanned shutdowns and ensures pressure equipment is always within safe operating limits, maximizing uptime, minimizing risk.

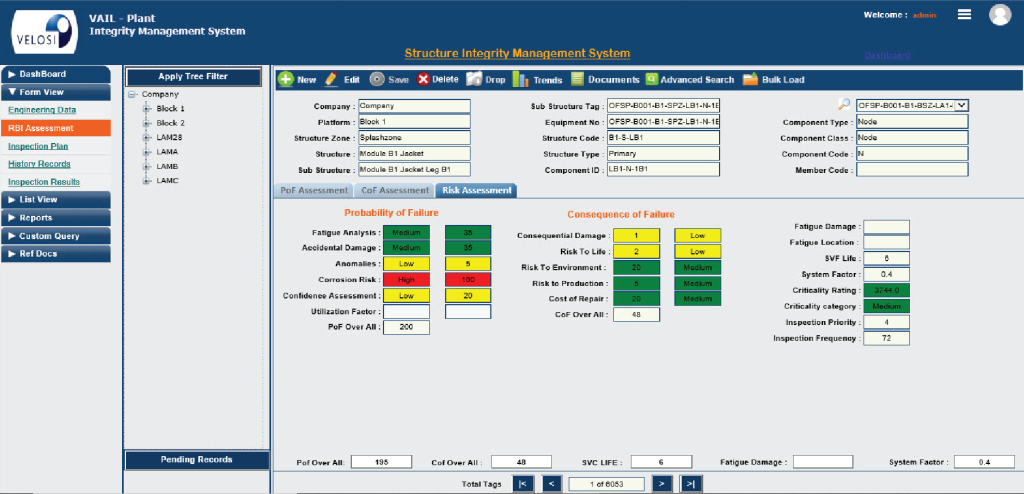

Often overlooked but critically important, SIMS targets mechanical structures like pipe racks, support beams, platforms, and storage frames. SIMS utilizes risk-based inspection planning of onshore and offshore steel structures based on AISC and API RP2 SIM industry standards. It ensures that your infrastructure is ready to withstand the operational and environmental loads throughout its lifecycle.

Key Features:

- Structural risk ranking based on criticality and location.

- RBI assessment

- FMEA analysis

- Condition-based inspection scheduling.

- 3D modeling and defect mapping.

Structural failures are not just costly, but they cost lives. SIMS ensures that structural stability should always be a priority on the list.

Benefits of a Robust Mechanical Integrity Solution

Implementing mechanical integrity via VAIL Plant® is not just about compliance; it is about value creation.

- Safety First: Protect personnel and the environment from asset-related failures.

- Zero Unplanned Downtime: Shift from reactive fixes to predictive maintenance.

- Audit-Ready: Meet international standards with traceable documentation.

- Operational Excellence: Extend asset life while optimizing performance and costs.

- Smart Decision-Making: Turn your inspection and asset data into business intelligence.

Conclusion

Mechanical integrity is one of the most critical aspects of industrial reliability, which serves as the foundation. Moreover, with the right tools like VAIL-Plant® and its modules (APMS, PEMS, SIMS), you can create a culture of integrity that scales with your operations.

At Velosi, we assist clients worldwide and implement mechanical integrity solutions that don’t just meet industry expectations but exceed them. Because in a world of rising risks, aging infrastructure, and complex regulations, true integrity begins with mechanical resilience.

Enhance overall mechanical integrity through an ultimate software solution, VAIL Plant®.

Contact us today and sustain your assets the right way!

Stay connected for more blogs!

Please contact us for more information and assistance.