Introduction to Integrity Operating Window – Pipeline Integrity

- December 15, 2022

- Posted by: Velosi Author

- Categories: Asset Integrity, Insights

What is an Integrity Operating Window?

An integrity operating window is a set of guidelines that ensure the integrity of a system. These guidelines in place make sure that any changes to the system can be done without affecting its performance. If any changes are incorporated, they must execute within this window and not outside it.

An IOW can be further defined as a limit established for the parameters of a process that may directly affect the integrity of fixed equipment and pipes. Deviation from these operating parameters increases the likelihood of degradation. A unit operating parameter can be thought of as a subset of a larger group of operational parameters. Degradation will likely be predictable if operations are kept within these limits; however, this does not necessarily mean that damage rates will be low.

An Integrity Operating Window’s purpose is to protect an operating system’s stability and reliability. Moreover, it also ensures data integrity and security; well defining the time an operator may take to incorporate changes to a system without risking its availability or functionality, as well as keeping a record of when the change must be reversed for data to remain consistent and unaltered.

What is PIMS?

Pipeline assets are important yet complex to manage and can be disastrous causing damage if they fail. When we talk about the functioning of (the Pipeline Integrity Management System (PIMS), it can be put forward as a system that manages pipeline inspections, maintenance, corrosion monitoring, testing, and asset evaluation. This type of system ensures effective management.

While we know a system has to be constantly monitored for effective productivity, it is important to establish and monitor limits to standardize process variables that could somehow affect the integrity or reliability of process equipment.

Integrity Operating Windows (IOW) within PIMS are practical for storing the desired monitoring data into one document. Moreover, IOW particularly monitors the essential parameters of a chemical process.

API RP 584, Integrity Operating Windows (IOWs)

Facilities must establish equipment-operating limits to prevent excessive equipment degradation and unnecessary equipment failures.

In particular, API RP 584 consists of all the necessary information about IOW. Additionally, it sets forth guidelines for creating, documenting, and implementing IOWs. In addition, API RP 584 presents ways to monitor and measure variables. Moreover, existing IOW programs can be reviewed and updated with integration guidelines under safety practices.

Integrity Operating Window-PIMS Architecture

The Integrity Operating Window-PIMS Architecture provides a robust and secure operating environment for the deployment of applications. Moreover, PIMS architecture will ensure an integrated security framework, which shall enforce the system’s integrity and prevent unauthorized access to data. IOW and PIMS architecture work subsequently by implementing precise control policies and integrity verification by preventing access to unauthorized data. The architecture imparts a consistent framework to protect asset integrity overall.

Importance of Integrity’s Operating Windows

Isn’t productivity a major concern for every business? Operating organizations are at high risk while competing to improve business productivity. Failure of an asset will critically have a consequential impact on the business overall, including factors of health, safety, environment, and business growth. IOW plays a significant role in safeguarding assets’ integrity and reliability, which will enhance asset performance and generate business productivity.

An IOW Can Help Your Business Achieve Major Milestones

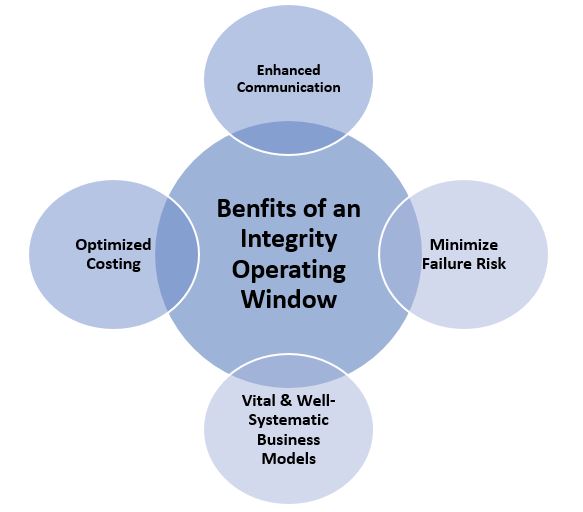

To conclude, leading IOWs benefits can help businesses achieve major milestones. It is particularly designed to provide high-level overviews regarding the criticality of assets and their performance. Moreover, asset integrity management accounts for sustainable and constantly improving business practices, It is highly desirable to incorporate an IOW program into existing Risk Based Inspection programs as this enhances their capabilities and helps predict, locate, and proactively recommend actions to prevent incidents. A well-established IOW program will provide real-time notifications to identify risks on time. The foundation of equipment operating limits is imperative to prevent unnecessary equipment failures and excessive degradation of the equipment. Last but not the least, the integrity-operating window is determined by considering factors like customer expectations, competition, and industry standards.

Please contact us for more information and assistance.