- December 28, 2025

- Posted by: Velosi Author

- Categories: Asset Integrity, Software

Pipeline corrosion is one of the critical negative factors in the oil and gas industry. When the audits mark ageing steel across long routes. You are dealing with rough terrains, tight deadlines, and strict regulators. You want less stress, fewer surprises, zero bottleneck situations, and a system that is reliable, safe, and keeps you one step ahead.

The CPMS (Cathodic Protection Management Software) assists oil and gas operations through a simple, steady workflow to track, record, and control pipeline protection with accurate cost and time efficiency.

What Is The CPMS: VAIL-Plant® Cathodic Protection Management Software Module in Oil & Gas?

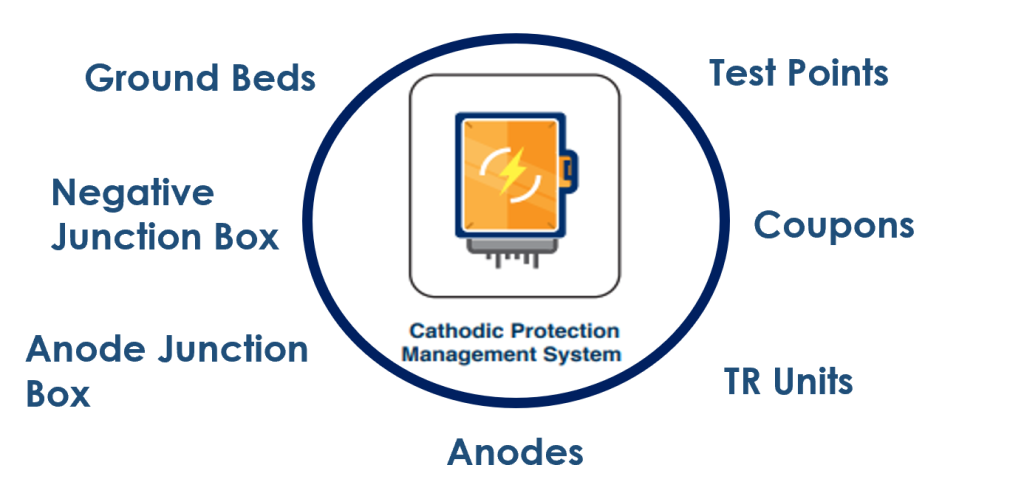

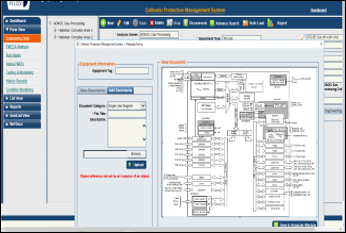

The CPMS module is part of the VAIL-Plant® platform, built to manage cathodic protection systems used across oil and gas pipelines and facilities.

It integrates assets such as transformer-rectifiers, ground beds, junction boxes, coupons, and test points. The custom-built module complies with standard guidelines such as NACE and supports inspection plans, risk scoring, and engineering records.

Key Features of Cathodic Protection Software Which Matter in the Oil & Gas Industry

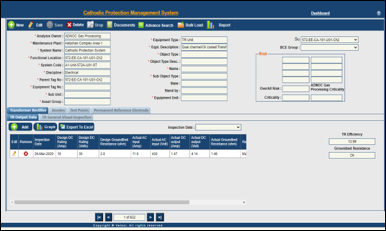

- Dashboard that shows field and pipeline status in one view.

- A seven-level structure to organize large CP networks.

- Design and construct data stored in a centralized network.

- Field test scheduling for crews working on remote lines.

- Trend charts that show early warning signs.

- Custom Query & Reporting for fast decision-making.

- FMECA tools to help teams identify weak points early.

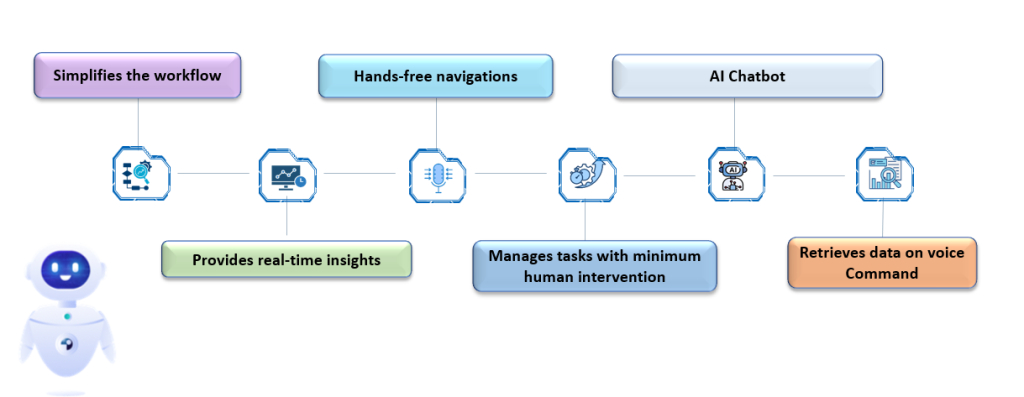

- Sara (AI-Powered Voice Assistant) & Sara-Bot.

SARA-Streamlining Workflows in VAIL-Plant® CPMS

Why Oil & Gas Teams Need Cathodic Protection Software

Oil and gas pipelines move through deserts, offshore zones, cities, and remote regions. Corrosion doesn’t wait. One missed reading can lead to a costly repair. Teams often deal with:

- Difficult-to-reach areas

- Scattered inspection data

- Heavy paperwork

- Delayed updates

- Pressure to meet compliance

But they prioritize:

- Clear readings

- Stronger control

- Accurate trends

- Less manual checking

- Proof of compliance

CPMS provides teams with a transparent and concise overview of what’s happening. Identify problems early, plan, and resolve issues before they escalate into shutdowns.

How CPMS (VAIL-Plant® Cathodic Protection Management Software) Works in Oil & Gas Operations

Visualize a long oil pipeline running under soil, passing through wet zones, salt patches, and high-temperature areas. Corrosion hits each section differently. Cathodic protection works like a shield around that steel.

The CPMS module tracks the strength of that shield. Field crews enter test point readings from remote sites. The system logs every number. When a reading drops, the software highlights it. You don’t dig for answers. They appear on your dashboard instantly. A digital supervisor, watching your CP system 24/7.

Where Accurate Data Can Strengthen Operations

Add numbers that speak to oil and gas:

- “Pipeline leaks caused by corrosion account for X% of failures in oil and gas networks.”

- “Early detection through CP monitoring reduces repair costs by Y%.”

- “Digital CP tracking can reduce field inspection time by Z%.”

When data is segregated into accurate numbers, precision is guaranteed.

Key Takeaway for Cathodic Protection Software

With CPMS, each reading appears instantly. When the system detects a drop in protection potential, it flags it. The maintenance team instantly knows where to check. No guesswork. No delays.

Conclusion

If you’re responsible for pipeline integrity in oil and gas, CPMS gives you steady control. It keeps readings clear, corrosion in check, and your team working with confidence. When you see the system catch issues early, you’ll understand its real value.

Real-Time Insights, Precision Monitoring, Zero-Failure Integrity with Velosi’s Cathodic Protection Software!

Please contact us for more information and assistance.

Stay connected for more blogs!