- March 23, 2025

- Posted by: Velosi Author

- Categories: Asset Integrity, Insights, Software

Introduction to Transmitters Integrity Software

In oil and gas operations, every asset matters; among them, transmitters stand out as components ensuring both safety and efficiency. These vigilant devices oversee metrics, such as pressure levels and flow rates, supplying data essential for seamless and secure operations.

Many operational teams often wonder about the recurring issue of transmitter failures. They seek ways to improve the coordination between transmitter maintenance and overall electrical system integrity management. The key concern is finding solutions to these challenges without causing disruptions to our operations.

At Velosi, we have developed a transmitter integrity software solution that not only addresses these pain points but seamlessly integrates with your existing Electrical System Integrity Management (ESIM) framework.

The Real-World Transmitter Challenges You’re Facing

If a pressure sensor malfunctions during production times, it’s not just an annoyance—it poses a safety risk and impacts profits for sure.

If you’re like most of our clients in the oil and gas sector, you’re probably dealing with:

- Unpredictable failures in critical environments: When a pressure transmitter fails during a high-production period, it’s not just an inconvenience—it’s a potential safety hazard and a definite hit to your bottom line.

- Maintenance team issues: Maintenance teams are under a lot of pressure as their technicians are skilled but unable to be in place at the time. Without tools at their disposal, they frequently find themselves reacting to problems rather than proactively addressing potential issues.

- Compliance documentation Chaos: Maintaining comprehensive records for regulatory requirements shouldn’t require a separate department, but many teams find themselves drowning in paperwork rather than focusing on actual system integrity.

- Disconnect between transmitter maintenance and broader ESIM: Your electrical systems and instrumentation should work in harmony, but too often they’re managed in silos, creating efficiency gaps and potential safety blind spots.

Bridging the Gap: How Transmitter Integrity Connects to ESIM

Your transmitters aren’t just assets; they are parts of your larger electrical setup that must function smoothly together. This is where Electrical System Integrity Management (ESIM) offers a structure to guarantee the dependability, safety, and effectiveness of all resources.

But here’s the reality many operations face: while ESIM programs address the big picture, transmitters often fall into a gray area between instrumentation and electrical systems. The result? Critical gaps in your integrity management approach.

Velosi’s transmitter integrity software serves as the crucial bridge between your instrumentation maintenance and comprehensive ESIM strategy. By integrating transmitter monitoring and management within your broader electrical system approach, you gain:

– Unified visibility across all system components

– Coordinated maintenance scheduling that optimizes resources

– Consistent compliance documentation for all electrical and instrumentation assets

– Improved safety through holistic system monitoring

– Enhanced reliability by identifying system-wide patterns and potential failure points

Top 10 Benefits of Velosi’s Transmitter Integrity Management

- Accurate Mean Time between Failures (MTBF) and Mean Time to Repair (MTTR) calculations.

- Efficient Failure mode, effect, and criticality analysis, and their criticality matrix.

- Run time Operator history and generic reliability data recording

- Hierarchy development and management

- Design/operational data capturing

- Functional data recording

- Precise Plant Maintenance Routines (PMR) generation

- Well-maintained Work order and work pack generation

- Inspection history recording

- Maintenance history recording & failures, and replacements recording.

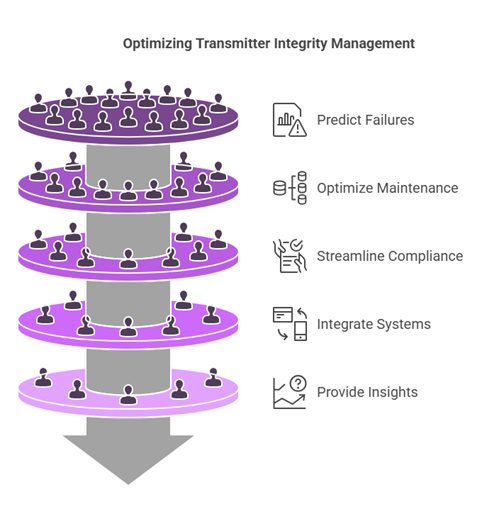

Five Ways Velosi’s Software Transforms Your Transmitter Integrity Management

Our transmitter integrity software is designed in response to the specific challenges we’ve heard from maintenance teams, operations managers, and safety officers across the oil and gas industry. Here’s how it addresses the bottleneck operations.

- Predicts Failures Before They Impact Operations

Rather than unwanted alarms, our software continuously monitors transmitter performance parameters and identifies subtle degradation patterns weeks or even months before failure occurs. One offshore platform using our solution reported a 78% reduction in unexpected transmitter failures within the first year of implementation.

- Optimizes Your Maintenance Resources

Velosi’s software provides the data-driven insights to calibrate exactly when needed- no more, no less.

The software analyzes performance data to recommend optimal maintenance intervals for each transmitter based on its actual performance, not just generic manufacturer guidelines. This approach has helped our clients reduce maintenance costs by an average of 23% while improving reliability.

- Streamlines Compliance Documentation

Regulatory compliance shouldn’t be this challenging. Our software automatically generates comprehensive documentation of all transmitter testing, calibration, and maintenance activities, creating an audit-ready trail that satisfies even the most stringent regulatory requirements.

- Integrates Seamlessly with Your Existing ESIM Framework

Your transmitter’s integrity management shouldn’t exist in isolation from your broader electrical system management. Our software is designed to integrate with your existing ESIM programs, providing a cohesive view of system health and enabling coordinated maintenance planning across all electrical and instrumentation assets.

- Provides Actionable Insights, Not Just Data

Many monitoring systems overwhelm users with data without providing clear direction. Our transmitter integrity software uses advanced analytics to translate complex performance data into straightforward action items for your team, prioritized by criticality and potential operational impact.

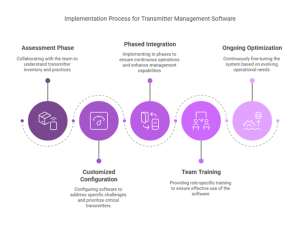

The Implementation Journey: Practical, Not Disruptive

We understand that any new technology implementation in the oil and gas industry needs to enhance operations without disrupting them. That’s why we’ve designed our implementation process to be thorough but minimally invasive:

- Assessment Phase: We work with your team to understand your specific transmitter inventory, existing maintenance practices, and integration requirements with your ESIM framework.

- Customized Configuration: Every operation is unique. We configure our software to address your specific challenges, prioritizing the most critical transmitters and processes first.

- 3. Phased Integration: Implementation occurs in carefully planned phases, ensuring continuous operations while gradually enhancing your integrity management capabilities.

- Team Training: Your people make the difference. We provide comprehensive training tailored to different user roles, from maintenance technicians to management.

- Ongoing Optimization: Implementation isn’t the end—it’s the beginning. We continue working with your team to fine-tune the system based on your evolving operational needs.

The Business Case: Quantifiable Returns on Your Investment

In today’s challenging market conditions, every investment needs clear justification. Our clients typically experience:

– 65-85% reduction in unexpected transmitter failures

– 20-35% decrease in overall maintenance costs

– 40-60% reduction in compliance documentation time

– Extended transmitter lifespan, often by 30% or more

– Improved operational efficiency through optimized maintenance scheduling

Beyond these direct benefits, clients report significant improvements in team morale and effectiveness as maintenance shifts from reactive firefighting to proactive problem prevention.

Taking the Next Step with Your Transmitter Integrity Management

Your transmitters are too critical to leave to chance. As the oil and gas industry continues to face pressure to improve efficiency while maintaining refined safety standards, integrated approaches to system integrity are no longer optional—they are essential.

Velosi’s transmitters integrity software provides the missing link between your instrumentation maintenance and comprehensive ESIM strategy, delivering immediate operational and long-term strategic benefits.

Ready to transform your approach to transmitter integrity management?

Contact Velosi for a personalized assessment of your current transmitter maintenance practices and discover how our software can address specific challenges within your ESIM framework.

Because in an industry where both safety and efficiency are non-negotiable, having the right tools makes all the difference.

Stay connected for more blogs!

Please contact us for more information and assistance.