Significance of Pipeline Risk Assessment

- February 6, 2024

- Posted by: Velosi Author

- Categories: Asset Integrity, Insights

Pipeline risk assessment is crucial in identifying risk factors. It is a systematic approach to identifying potential hazards that could lead to pipeline failure and involves evaluating the likelihood of a risk event occurring and associated potential consequences.

Is Pipeline Risk Assessment an Important Factor in the Petroleum Industry?

Indeed, this risk assessment plays an important part in managing the functionality and reducing all environmental hazards. By enhancing safety, here are some common failures that are prevented by a solid risk assessment plan.

- Pipeline leakages and the release of hydrogen sulfide.

- Major oil spills are followed by minor oil spills (mixing two oils that change in density & and viscosity).

- Explosions

Important Steps Involved During Pipeline Risk Assessment

- Risk Identification:

The first step experts work on is to identify the major threatening factor that can damage the pipelines and then eliminate it. This risk can be in the form of natural problems such as forces, underlying corrosion or rust issues, and even due to third-party pressures.

- Risk Analysis:

Once the issues are determined, it is time to list them according to their effects and importance. For instance, if the pipelines are leaked as well as damaged by corrosion. The experts first consider leakage as the main problem that needs to be resolved. Now, considering the importance of the factor next on the list, it is analyzed properly.

- Risk Management:

Furthermore, using the appropriate techniques, the pipelines are fixed. Depending on the threat level, each part of the pipeline is fixed according to the limit so that it doesn’t cost a lot and can be fixed precisely.

- Testing:

The last phase of this risk assessment is to check if the pipelines are working properly. Different tests are performed but with proper safety so that there cannot be any type of major or minor explosions. Once the tests are done, the pipelines are ready to work.

What are Risk Assessment Methodologies?

As well as two methodologies for risk assessment, there are several basic principles associated with the petroleum industry that should be considered.

First, the qualitative risk assessment is used by small businesses that don’t face any risks of getting destroyed at all. Therefore, it is the basic principle in the construction field. Using techniques like matrix analysis, HAZOP studies, and FMEA, this risk assessment identifies the impact of a certain risk on expert judgments and experience.

On the other hand, quantitative risk assessment is the more advanced principle of this petroleum and construction industry. It works by using techniques like fault tree analysis, event tree analysis, Monte Carlo simulation, and probabilistic risk assessments. Thus, including numbers and experimental data, this risk assessment provides solutions for preventing the common threats to the pipelines.

Common Safety Hazards & Incidents of Pipeline Leakages:

- Explosions & Fires:

We all know that the oil and gas industry involve highly flammable gases that can lead to sudden blowouts if not handled properly. If there is any leakage in the pipelines underground, then it might lead to explosions and fires all around the plant. Which can potentially lead to life losses, environmental damage, and even material harm.

- Transportation Accidents:

Another factor that can lead to oil and gas loss is transportation accidents. Sometimes the trucks and cargo shifting oils can leak due to any sort of circumstances. This ultimately leads to environmental damage and even road accidents from slipping of vehicle tiers.

- Working Risks:

The petroleum plants are pretty enormous to work on. The workers mostly perform height-based tasks. Therefore, it is a great risk that they might fall from this extreme height. Moreover, using heavy machinery can harm the employees. Thus, safety measurements should be an utmost priority, especially in the industry sector.

The release of harmful gases through a pipeline leakage or explosion can lead to various environmental hazards. Let us have a look at how this can have an impact on the environment.

|

Environmental Impact |

Description |

|

Oil Spills |

Accidental release of oil during transportation, storage, or exploration causes contamination of soil, water bodies, and marine ecosystems, severely impacting wildlife and local economies. |

|

Air Pollution |

Burning of fossil fuels (oil and gas) in refineries, power plants, and vehicles releases greenhouse gases and pollutants, leading to smog, climate change, and adverse effects on human health. |

|

Water Contamination |

Extraction methods, especially hydraulic fracturing (fracking), can contaminate water sources if chemicals aren’t managed well, posing risks to groundwater, aquatic life, and community water supplies. |

|

Habitat Destruction |

Exploration and production activities often require land clearing and infrastructure construction, leading to habitat destruction, fragmenting ecosystems, and threatening biodiversity in sensitive areas. |

Benefits of Pipeline Risk Assessment

Understanding Pipeline Risk Assessment Pipeline networks involve complexity, that carries not just important resources, but also possible risks. This is where pipeline risk assessment comes in, helping to prevent unexpected problems. But it’s not just about avoiding issues, this method also brings many advantages for those who run the pipelines, the local communities, and even the environment. Let’s have an overview of why pipeline risk assessment is an essential part of managing risks.

- Enhanced Safety and Reliability: Pipelines are lifelines carrying essential resources, and their integrity is paramount. Pipeline risk assessment identifies potential threats, from corrosion and external damage to operational issues, enabling operators to prioritize preventive measures to reduce potential accidents. This methodology leads to fewer leaks, ruptures, and disruptions, safeguarding public safety and environmental well-being.

- Optimized Resource Allocation: Resources are precious, and pipeline risk assessment helps you invest them wisely. By prioritizing high-risk segments and maintenance interventions, you can maximize the effectiveness of your operations and budget. This proactive approach minimizes costly reactive repairs and unplanned downtime, ensuring a smooth and efficient flow of resources.

- Regulatory Compliance and Stakeholder Confidence: Regulatory bodies worldwide, like the PHMSA in the US, mandate pipeline risk assessment as a cornerstone of safety management. Conducting thorough assessments demonstrates your commitment to compliance, fostering trust with regulatory authorities and boosting your reputation as a responsible operator.

- Improved Decision-Making: Pipeline risk assessment equips you with data-driven insights, empowering you to make informed decisions. By understanding the likelihood and impact of potential risks, you can optimize route selection, material choices, and operating procedures, leading to robust and resilient pipelines.

- Reduced Environmental Impact: Pipeline incidents can have severe consequences for the environment. Pipeline risk assessment proactively identifies threats to sensitive ecosystems and waterways. Which allows for minimizing potential ecological damage. This commitment to environmental safety leads to positive community relations and promotes sustainable resource transportation.

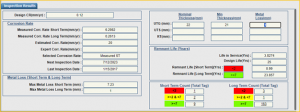

Pipeline Integrity Management System (PIMS) Offshore & Onshore – VAIL PLANT

Implementing VAIL PLANT PIMS isn’t just about acquiring software; it’s about allying with a team of experts dedicated to your pipeline’s safety and success. Velosi’s VAIL PLANT PIMS, offers comprehensive support, from initial implementation to ongoing processes and data analysis. This ensures that you get the most out of the system and achieve optimal results.

Advantages of the VAIL Pipeline Integrity Management System (PIMS)

- Enhanced Risk Prioritization: VAIL PLANT PIMS goes beyond simply identifying risks. It utilizes advanced algorithms and data analysis to rank threats based on their likelihood and potential impact.

- Data-driven Decision-making: VAIL PLANT PIMS equips you with a wealth of data, including inspection records, environmental factors, and operational history. This data-driven approach allows you to make informed decisions about maintenance, repair, and replacement, optimizing your pipeline’s lifespan and performance.

- Easy Regulatory Compliance: Navigating the complex network of pipeline regulations can be difficult. VAIL PLANT PIMS simplifies compliance by incorporating relevant standards and best practices into its risk assessment framework. Which ensures operations within regulatory boundaries and cost-efficient strategies.

- Streamlined Inspection Management: VAIL-PLANT streamlines the process by creating inspection plans, scheduling tasks, and tracking results. This centralized platform keeps your inspection program organized and efficient, maximizing its effectiveness.

Conclusion

Investing in your pipelines isn’t just about the metal; it’s about investing in safety, reliability, and a sustainable future. By actively embracing pipeline risk assessment through Velosi’s VAIL PLANT software, you will cultivate a culture of safety, build trust, optimize resources, and safeguard the environment, all while ensuring the smooth flow of the resources that sustain our society. Moreover, safeguarding your plant’s integrity through the most cost-effective solution.

Please contact us for more information and assistance.