Risk-Based Inspection (RBI) study for the PetroKemya Utilities-South & Polystyrene Plants through Piping Re-circuitization with VAIL-Plant® APMS Mechanical Integrity (MI) module

Scope

The Project Scope of work includes Re-circuitization & Risk Based Inspection study of piping systems for the following Units of PetroKemya Utilities-South & Polystyrene Plants:

- Corrosion Loop Drawings & Assigning Damage Mechanisms

- Corrosion Loop Description

- Development of Integrity Operating Windows

- Inventory Group Drawings

- Piping Circuit Drawings & Piping Circuit Masterlist

- SAP Upload Template to create New Assets

- RBI Meridium Templates for Risk Assessment

- RBI Meridium Template for Corrosion Loops

- RBI Meridium Template for TML Structure creation

- Inspection Strategies creation and Management in Meridium

- Link the RBI Component with Corrosion loops in Meridium

- CML marked Isometric Drawings

- Redundant Old Piping Circuits and Old Inspection Tasks in SAP and Meridium

Process

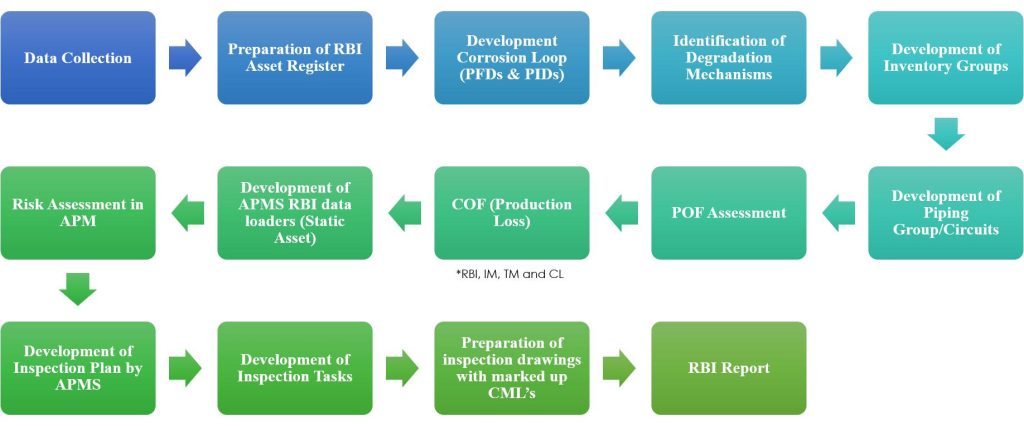

The methodology of this project involves a comprehensive approach set forth to ensure essential elements of project scope as:

- The line list, Engineering Data, Piping Material / Class Document to develop the Asset Register for all Piping.

- Development of Material Selection Diagrams.

- Process Flow Diagrams and Heat and Material Balance have been used to develop Corrosion Loops and assigning Degradation Mechanisms for each corrosion loop.

- PID to reflect the demarcation of Corrosion Loops from PFDs.

- Development of Corrosion Loop Description Document for each corrosion loop marked on PFDs.

- Utilization of Asset Register to group Piping in a piping circuit and mark the boundary of each piping circuits on PID and developed Piping Circuit Drawings.

- Creation of marked Inventory Groups with clear boundaries on PFDs.

- Utilization of Corrosion Loops with certain Degradation Mechanisms to identify critical process parameters and Integrity Operating Windows for each loop.

- Development of SAP template to create assets in SAP.

- Development of SAP Templates to link the lines with Superior Equipment (Piping Circuits)

- Development of RBI Templates to perform Risk Assessment and Generation Inspection Plan in GE Meridium.

- Preparation of SAP Templates to create work orders for Inspection Tasks.

- Development of 580 Corrosion Loop Template for create and link corrosion loops with Piping circuits in GE Meridium.

- Creation of CML markup drawings to highlight Inspectable locations.

- Development of TML Template as per CML markup drawings and created TML Structure in GE Meridium.

- Highlighting and de-activation Old Piping Circuits and Inspection Tasks in GE Meridium and SAP.

Outcome

Velosi’s team of expert individuals successfully conducted Risk-Based Inspection (RBI) study for PetroKemya Utilities-South & Polystyrene Plants utilizing APMS Mechanical Integrity (MI) module as per COMPANY requirements.

The Project was a successful completion, which not only met but exceeded client expectations. Despite facing numerous challenges throughout the process, our dedicated team demonstrated exceptional resilience and adaptability, ensuring that all objectives were achieved. The project culminated in the delivery of high-quality deliverables that aligned with the client’s vision and requirements. This success reflects our commitment to excellence and our ability to navigate complexities while maintaining a focus on client satisfaction.

Deliverables

Team Velosi developed and submitted following deliverables:

Development of MFD’s (Metallurgical Flow Diagram for equipment and piping)

Corrosion Loops

- Create Corrosion Loops Diagrams based on Process Flow Diagrams and P&ID’s.

- Assign Critical Process Parameters to Respective corrosion loops.

- Define Integrity Operating Windows for the identified Critical Process Parameters as per

- corrosion loops.

- Assign potential degradation mechanism per corrosion loops according to API 571 “Damage Mechanisms Affecting Fixed Equipment in the Refining Industry”.

- Update Corrosion Loops and Damage Mechanism in GE digital APM software.

- Delete not applicable Corrosion Loops and Damage Mechanism in GE digital APM software.

- Develop Corrosion Loops Master List per plant.

Inventory

- Develop inventory drawings for all piping circuits (Inventory to be reviewed and approved by PETROKEMYA Team).

- Calculate inventory for all piping circuits (Inventory to be reviewed and approved by PETROKEMYA RBI team).

Piping Circuitization

- Perform piping Circuitization based on international / SABIC guidelines.

- Create Piping circuits diagrams based on P&ID’s.

- Create Piping Circuits Master list per plant.

- Crate list of Areas of Deterioration for Piping Systems Masterlist (injection points, mixing

- points, deadlegs, Soil-to-air interfaces, small bore piping).

Data Migration in SAP (MD)

- Create new Piping Circuits with new taxonomy in SAP using PMDB Software.

- Link lines to respective Piping Circuits (Superior Equipment) using PMDB Software.

- Deactivate redundant circuits using PMDB Software.

Corrosion Isometrics

- Define Condition Monitoring Locations for new assets based on degradation mechanism and areas of deterioration for new piping systems.

- Create Condition Monitoring Locations Masterlist for new assets based on degradation mechanism and areas of deterioration for piping systems.

- Create Condition Monitoring Locations drawing on merged isometrics for new piping

- Verify corrosion isometrics on field for geometry, interconnections and flow orientation (Vessel Trim Shall not be part of Piping Circuits).

Data Migration in GE digital APM software

- Create Thickness Monitoring Locations Groups / Thickness Monitoring Locations Points in GE digital APM software TM Module based on defined Condition Monitoring Locations Data.

- Align old Thickness Monitoring Locations Data to New Thickness Monitoring Locations Structure in Thickness Management Module in GE digital APM software.

- Create time-based inspection tasks in GE regarding Areas of Deterioration for Piping Systems (injection points, mixing points, deadlegs, soil-to-air interfaces, small bore

- piping).

- Deactivate old Piping Circuits / Components in Meridium.

RBI Assessments for NEW assets

- Identify & Assign RBI Component for Piping Circuits.

- Link RBI components to respective corrosion loops in GE digital APM software.

- Establish new consequences for all new piping circuits. (Consequences to be Defined with PETROKEMYA RBI Team Members).

- Develop datasheet of estimated corrosion rate based on design data. (CONTRACTOR shall share basis for material selection including the estimated corrosion rates and corrosion rates from published standards).

- Conduct RBI assessment for all new piping circuits in GE digital APM software.

- Develop new inspection tasks (based on RBI analysis) in GE digital APM software based on PETROKEMYA guidelines (Follow OMS-433 – RBI Methodology).

- Develop RBI master List per plant on format provided by PETROKEMYA.

Data Migration in SAP (PM / MD)

- Submit request to create new inspection strategies in SAP System (Time Based / RBI) using PMDB Software.

- Submit request to delete previous RBI tasks in SAP System using PMDB Software.