RBI Implementation Project – SHELL LNG Canada (LNGC)

Scope

The Project Scope of work includes Risk Based Inspection of the static equipment and piping for the following Units of Shell LNG:

- Inlet Facilities

- Acid Gas Removal Unit

- Dehydration Unit

- Mercury Removal Unit

- Liquefaction Unit

- Incinerator Unit

- Condensate Stabilization Unit

- Refrigerant Production Unit

- Refrigerant Storage

- LNG Storage Tank 9T-3101 (Full Containment Tank)

- Condensate Storage

- LNG Storage Tanks and Loading System

- Condensate Storage and Loading

- Essential Power Generation System

- Heat Transfer Fluid System

- Cooling Water System

- Tempered Cooling Water System

- Water Supply (Intake Station) and Treatment System

- HP/LP Fuel Gas System

- Defrost Gas System

- Portable and Service Water System

- Demineralized Water Treatment Facility

- Instrument and Tool Air System

- Nitrogen System

- Diesel Fuel System

- Fire Fighting System

- Pressure Relief and Liquid Disposal System

- Drainage and Effluent Treatment System

Process

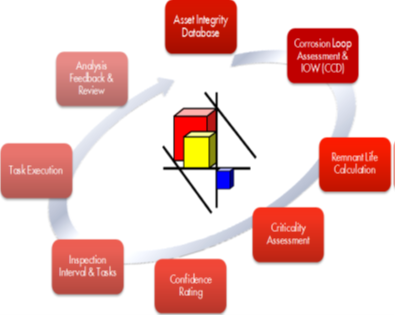

The methodology of this project involves a comprehensive approach set forth to ensure essential components of the project scope as:

Outcome

Velosi’s team of expert individuals successfully conducted a Risk-Based Inspection (RBI) study for Shell LNG utilizing Shell w-IMS as per LNG requirements.

The Project was a successful completion, which not only met but exceeded client expectations. Despite facing numerous challenges throughout the process, our dedicated team demonstrated exceptional resilience and adaptability, ensuring that all objectives were achieved. The project culminated in the delivery of high-quality deliverables that aligned with the client’s vision and requirements. This success reflects our commitment to excellence and our ability to navigate complexities while maintaining a focus on client satisfaction.

Deliverables

Team Velosi developed and submitted the following deliverables:

- s-RBI Report.

- Corrosion Control Document.

- Corrosion loops and lists of static equipment and piping tags by corrosion loop.

- Inspection and Test Plan.

- IMS Database.

- CML Setting Documents.

- ITP for First Non-visual Inspection event.