AIV / FIV Analysis for Re-Select and FEED Services For Nasr 100MBD Project Phase 2 for ADNOC Offshore

Scope

The Project Scope of work includes identifying and confirming the lines that are likely to fail due to AIV / FIV and carrying out a detailed fatigue analysis on the specific lines identified that warrant it. Further recommend measures and mitigation of fatigue failure due to acoustic for the identified system.

Process

The methodology of the study is in accordance with the Energy Institute Guidelines. The following study approach is adopted for AIV and FIV studies.

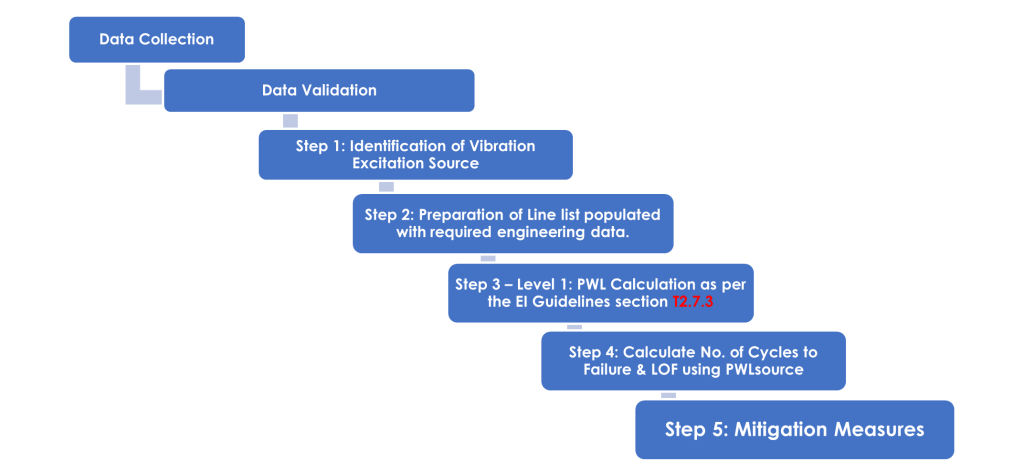

AIV assessment – The study was performed in accordance with Section T.2.7.3 of EI guidelines. The following approach has been adopted

- Collection of facilities engineering data; P&IDs, PFDs, isometric drawings, and other associated information.

- Identification of Acoustic Induced Vibration (AIV) Excitation sources.

- Calculation of the Sound Power Level (PWL) and corresponding Likelihood of Failure (LOF) scores.

- Segregation of the pipelines/piping systems suspected of risk of AIV failure based on the PWL & LOF.

- Mitigation measures by means of verification of locations and types of pipes support to mitigate and minimize acoustically induced vibration in accordance with Energy Institute (EI) Guidelines.

Work Flow for AIV studies

FIV assessment:

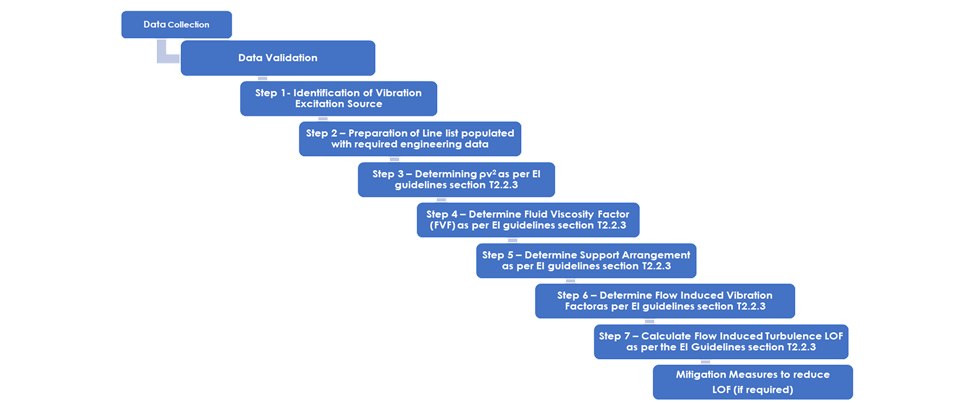

The study has been performed in accordance with section T2.2.3 of the Energy Institute Guidelines. The following study approach has been adopted.

- Collection of facilities engineering data; PFDs, P&ID’s, Isometric drawings and other associated information.

- Identification of potential high-risk areas in the piping system that may be susceptible to Flow Induced Vibration (FIV).

- Analysis of the process data, such as flow rates, fluid properties, and velocities.

- Calculation of the Kinetic energy (ρv2) of the piping and the Likelihood of Failure (LOF) accordingly as per the Energy Institute Guidelines.

- Segregation of the pipelines/piping systems suspected of risk of FIV failure based on the kinetic energy & LOF.

- Mitigation measures by means of verification of locations and types of pipes support to mitigate and minimize acoustically induced vibration in accordance with Energy Institute (EI) Guidelines.

Work Flow for FIV studies

Outcome

Velosi’s team of expert individuals successfully developed the Acoustic Induced Vibration (AIV) & Flow Induced Vibration (FIV) Methodology and Acoustic Induced Vibration (AIV) & Flow Induced Vibration (FIV) Study Report, along with appendices.

This project was successfully completed ahead of schedule, surpassing client expectations through meticulous planning and innovative problem-solving. Our dedicated team delivered high-quality outcomes that not only met the project specifications but also added significant value to the client’s objectives. Comprehensive feedback from the client highlighted their satisfaction with the exceptional quality of deliverables, which included detailed documentation, robust functionality, and user-friendly interfaces.

Deliverables

Team Velosi submitted the following deliverables:

- Acoustic Induced Vibration (AIV) Study Report

- Flow Induced Vibration (FIV) Study Report

The main content of the reports included all information used, methodology and approach taken, assumptions made, results, and recommendations. The following appendices were submitted along with the reports.

- Input Database

- Calculation sheet

- Calculation validation sheet

- Identified locations affected by AIV and FIV

- Isometric markups indicating the relevant measure, i.e., increased pipe wall thickness, full wrap pad, etc.

- P&IDs marked up

- Suggest mitigation measures to eliminate the impact of AIV/FIV