- August 25, 2025

- Posted by: Velosi Author

- Categories: Engineering, Insights

Introduction

Design verification in engineering is a structured process that ensures technical designs align with project specifications, codes, intended functionality, and regulatory requirements before any construction or commissioning. It’s the quiet shield between a good plan and a costly mistake.

Engineers don’t just draw; they take responsibility. Whether it’s a pressure vessel under ASME, a concrete tank under ACI, or a structural frame under BS or ASCE, designs must work both on paper and in reality. And that’s what design verification guarantees: not guesswork, not best intentions, but demonstrable compliance.

Complex global industries, from oil and gas to construction and manufacturing, require continuous assurance.

Importance of Design Verification

Because the risks of skipping it range from expensive fixes to structural failures. This is how responsible firms protect human life, financial investment, and regulatory reputation.

Design flaws are rarely obvious until it’s too late. A miscalculated load, an overlooked spec, it all adds up. Design verification works like a forensic audit on your plans. Before metal is cut or concrete gets poured, this process combines every dimension, material choice, load path, and compliance factor. Moreover, regulators demand it, and clients mainly rely on it.

Benefits of Design Verification

- Improved Safer and Reliable Operations

Early risk mitigation, minimized failure risks, and regulatory compliance ensure safer and reliable operations.

- Enhanced Cost and Time Efficiency

Avoiding unnecessary modifications, ensuring the development process, and minimizing overhead costs lead to enhanced cost and time efficiency.

- High Quality & Performance

Aligning with user requirements, potential performance challenges, and complying with performance specifications assures higher quality and performance.

- Improved Customer Satisfaction

Coordinating customer expectations and building trust leads to improved customer satisfaction.

- Refined Communication & Collaboration

With proper verification requirements, shared design functionality ensures refined communication and collaboration.

Design Verification Overview

The important aspects included in the design verification process are technical and support documentation with specified reasons.

Design Verification Should Include:

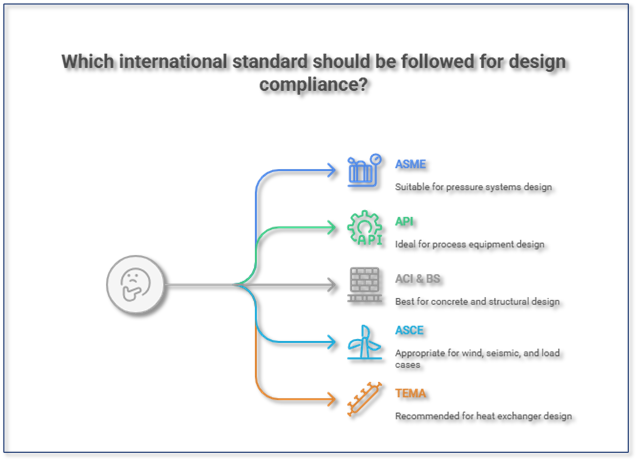

- Code Compliance Review: Designs must match the relevant international standards.

- ASME for pressure systems

- API for process equipment

- ACI & BS for concrete and structural design

- ASCE for wind, seismic, and load cases

- TEMA for heat exchangers

- Any deviation is flagged and not passed until corrected.

- Structural & Load Validation: From foundation loads to seismic response, everything’s rechecked. Are the stress values within limits? Will supports carry the weight? Are fatigue and thermal effects accounted for?

- Material Confirmation

Materials must be fit for service. Verification ensures the structured drawing supports the real-world environment, including:

- Corrosion zones

- High-pressure lines

- Offshore weather

- Safety & Functionality

Safety and functionality features include relief valves. Redundancies. Flow paths. Is the design operationally sound? Can it be maintained safely? Will emergency features function under duress?

- Drawing & Calculation Audit

All technical documents are verified for accuracy, completeness, and consistency. Any limitations or complications will mostly be linked to the design phase.

Primary Objectives of Design Verification

To identify design errors before they reach fabrication or field execution. That means all necessary steps to save money, time, accountability, and organizational reputation.

- Avoiding construction rework

- Avoiding failed inspections

- Avoiding non-compliance penalties

- Avoiding system downtime

- Avoiding safety incidents

What Industries Require Design Verification?

Most of them. Some of the biggest global sectors make it a built-in part of their project cycles:

Oil & Gas: Verification is needed for pressure vessels, pipelines, and offshore platforms.

Power & Energy: Substations, boilers, turbines, everything must meet regulatory codes.

Manufacturing: Mechanical assemblies, factory systems, and robotics setups are verified.

Construction: From retaining walls to commercial towers, compliance with ACI and BS codes is mandatory.

Marine & Offshore: Hull structures, risers, and deck equipment go through intense scrutiny.

In the UAE, for example, authorities like EAD and ADQCC require verified design reports before construction permits are issued. And it’s not just about ticking boxes, it is about proving that your engineering is safe and accountable.

Design Verification at Velosi

At Velosi, we don’t just design. We verify. This is where the independence comes in with qualitative results. We structure our design packages objectively for our reports and findings to be trusted by global regulators and clients.

Our process is technical. Transparent. And always traceable.

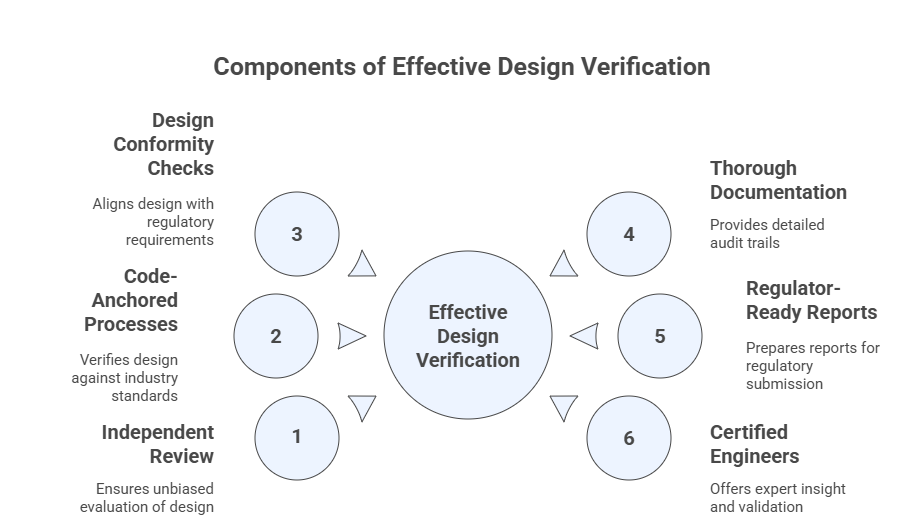

Key Advantages of Design Verification with Velosi:

- Independent engineering review

- Code-anchored verification processes

- Design compliance checks aligned with ASME, API, ACI, BS, and TEMA

- Thorough documentation of audit trails

- Regulator-ready verification reports

- Insight from certified engineers

Challenges Without Design Verification

Companies going further without a proper design verification phase can come through:

- Costly project delays after failed inspections

- Fabricated parts scrapped due to incorrect specs

- Non-compliance penalties from regulatory bodies

- Equipment failure after startup

- Injuries caused by preventable structural issues

Design verification secures the unexpected. Exclusion or improper execution can lead these potential risks to a reality.

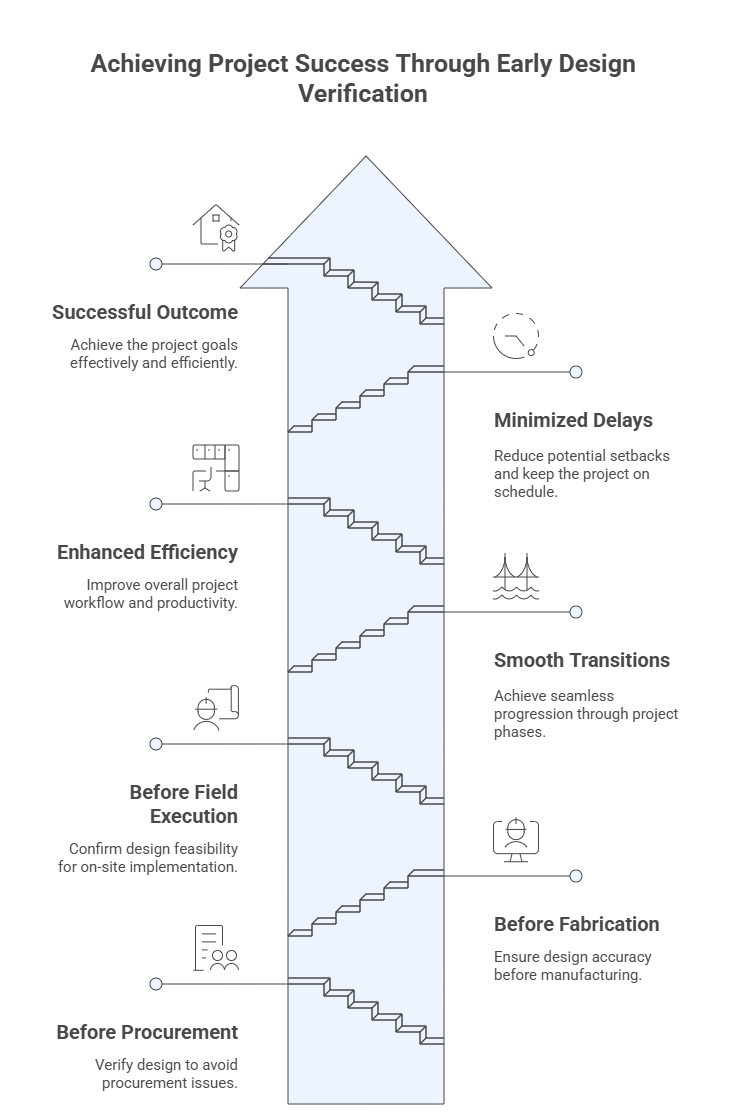

When Should Design Verification Happen?

Before procurement. Before fabrication. Before field execution. The earlier the design verification is performed, the fewer unexpected technicalities.

We’ve seen projects wait until the final stages to verify designs, only to face costly redesigns. Smart teams build it into the schedule right after design freeze and well before construction.

For Engineers, It’s About Trust

Engineers don’t operate on “should be fine.” They work on the proof. And verification is proof.

At Velosi, we’ve reviewed thousands of design packages—offshore platforms, refineries, bridges, tank farms, you name it. Each time, the mission’s the same: protect the client by testing the design against reality.

That’s not just a service. It’s an obligation.

Conclusion

To conclude, design verification isn’t just a best practice; it’s an industry expectation. In high-consequence sectors, unchecked assumptions are a liability.

If your project is heading toward construction, fabrication, or regulatory approval, make sure the design is verified. Because the real cost of failure isn’t in the drawings, it’s in the downtime, legal exposure, repair bills, and reputational hit.

Velosi’s expertise helps you avoid all unexpected risks with technical reviews that meet international expectations, satisfy regulators, and keep projects running smoothly.

Are you ready to verify your design package? Reach out to Velosi.

Our engineers state code, and our reports ensure compliance.

Please contact us for more information and assistance.

Related Services

Independent Verification Bodies (IVB) & Technical Integrity Verification (TIV)

Project Management Consultancy Services

Stay connected for more blogs!