- March 28, 2025

- Posted by: Velosi Author

- Category: Insights

What is Reliability Centered Maintenance?

Reliability centered maintenance (RCM) is an enterprise-wide preventive maintenance strategy that is strategically structured to optimize the maintenance programs within every facility. This professional methodology upkeeps asset condition monitoring and enhances maintenance planning to implement prioritized safety levels for all facility assets.

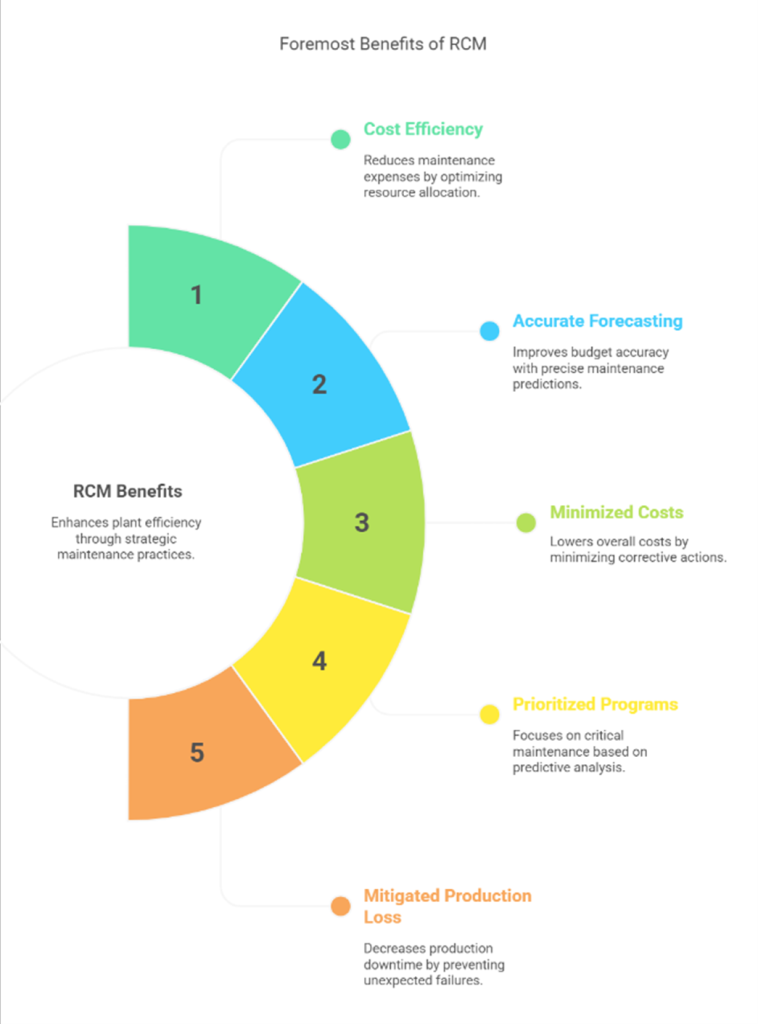

RCM Benefits

- Cost-efficient approach to plant maintenance.

- Accurate forecasting and scheduling of maintenance budgets.

- Minimizes corrective and overall maintenance costs.

- Prioritizes maintenance programs based on predictive and criticality schedules.

- Mitigates production loss due to unexpected failures of critical equipment.

Reliability Centered Maintenance (RCM) at Velosi implements precise and systematic methods in order to determine the most appropriate maintenance tasks to address each of the identified failure modes and consequences.

The main goal is to maximize equipment availability while reducing potential asset failure and the need to replace assets, thereby minimizing costs.

Utilizing industry’s best practices to optimize and manage customers’ data, make informed and timely decisions with cost-efficient strategies based on acceptable risk.

- BS EN IEC 60812

- SAE JA1011

- SAE JA 1012

- ISO-14224

- OREDA

Reliability Centered Maintenance (RCM) VS Maintenance Procedures

RCM prioritizes every asset according to specific needs, processes, monitoring, and maintenance strategy. While other ordinary maintenance procedures focus on the overall criteria without definite asset prioritization.

TOP SEVEN Questions for Reliability Centered Maintenance

- What are each asset’s intended functions and performance requirements?

- How is it possible for any asset to fall through its basic functionality?

- For every functional failure, what are the modes of failure?

- What leads to each mode of failure?

- How does each failure impact the process?

- What steps should be taken to predict and prevent potential failure?

- If a suitable proactive task cannot be identified, what should be done?

Optimize Efficiency with Reliability Centered Maintenance (RCM)

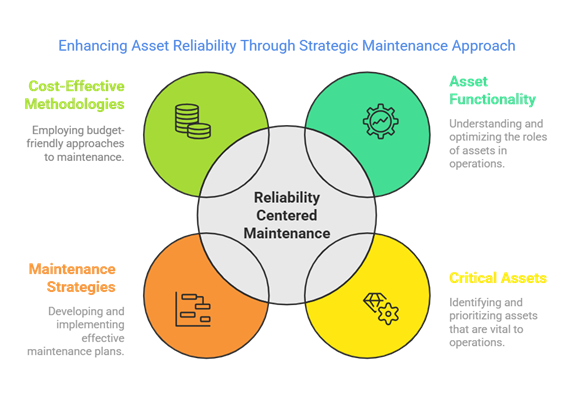

Reliability centered maintenance (RCM) identifies the exact functionalities of organizations that are willing to optimize their maintenance strategies and mitigate system failures through enhancing asset reliability and availability. The assets that are most likely to fail frequently or have significant implications from failure are the most critical ones. With a proper maintenance strategy and asset functionality, potential failure modes and their consequences can be easily identified and analyzed.

The best way is cost-effective maintenance methodologies that minimize potential failures. Such effective methodologies are then implemented to enhance the overall asset and facility reliability.

Transform your maintenance strategies with excellence – Reliability Centered Maintenance (RCM)

Your Ultimate Reliability-Centered Maintenance Software

Stay connected for more blogs!

Please contact us for more information and assistance.