RBI Implementation Project – ADNOC Sour Gas, Abu Dhabi, UAE

Scope

The Project Scope of work includes Risk Based Inspection of the static equipment and piping for the following Units of ADNOC SOUR GAS:

- Gas Gathering Systems

- Gas Processing Units

- Sulphur Recovery Units

- Utilities and Off-sites

- Product Pipelines

- Sulphur Station (Granulation)

Process

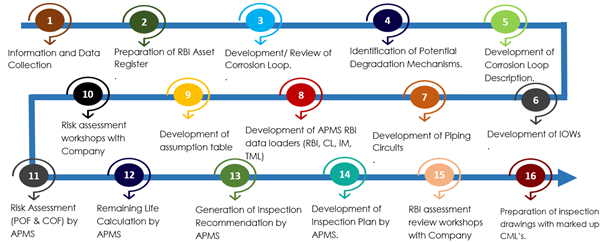

The methodology of this project involves the utilization of the APMS Mechanical Integrity (MI) module to implement RBI across ADNOC SOUR GAS operations. A comprehensive approach was set forth to ensure essential components of the project scope, such as:

Outcome

Velosi’s team of expert individuals successfully conducted a Risk-Based Inspection (RBI) study for ADNOC SOUR GAS Shah Plant utilizing the APMS Mechanical Integrity (MI) module as per COMPANY requirements.

The Project completed not only met but exceeded client expectations. Despite facing numerous challenges throughout the process, our dedicated team demonstrated exceptional resilience and adaptability, ensuring that all objectives were achieved. The project was concluded by submitting high-quality deliverables that aligned with the client’s vision and requirements. This success reflects our commitment to excellence and our ability to navigate complexities while maintaining a focus on client satisfaction and asset reliability.

Deliverables

Team Velosi developed and submitted the following deliverables:

- Validate /Update Asset Register.

Qualitative Risk Assessment List

- Development of Corrosion Loops and Piping Circuits (Marked up PFD and P&ID)

- Develop Corrosion Loop Descriptions (Physical Descriptions, Process Descriptions, Damage Mechanism Descriptions, IOW, etc.)

- Create Corrosion loops in APM.

- Corrosion loop-wise IOW identified list with lower, and upper limits, the criticality of IOWs to monitor, and its frequency of monitoring and alerts.

- Develop SAP (CMMS) Upload Files for piping circuits.

- Development of data loaders for RBI, IM and TM modules

- Validate and complete all data in all mechanical integrity modules (TML, IM and RBI)

- Development of Inventory Group – Equipment Boundaries

- RBI Assessment (POF & COF) based on APM -Semi-quantitative approach.

- Develop Inspection plan at component level (Scope, Extend, Technique etc.) m. Detailed Inspection plan for SPOF systems

- Identified Dead leg and injection points register and marked up ISOs and verify at site for physical availability.

- Inspection Isometrics with CML locations identified.

- Using current inspection history and Thickness data (Stored in APM and external sources) to calculate the required confidence and Corrosion Rate to be used in RBI.

- Create inspection task based on RBI recommendation in APM after managing RBI recommendation on Asset level.

- Prepare a summary integrity report including all used assumptions and RBI results based on Unit level.

- Prepare summary IOW report for all active Damage Mechanisms in ADNOC Sour Gas, including the DMs criteria/ inputs and DMs limits for (normal, warning & critical zones) based on Unit level. lower, and upper limits, the criticality of IOWS and its frequency of monitoring and alerts.

- Update and review the current TML -group and adjust based on RBI components.

- Set up an Inspection plan for identified SPOF systems.

- Piping: Create Piping Groups in SAP, Link Piping Tags to groups, RBI analysis on group level and generate inspection tasks and reports. TML data mapped to these new circuit levels.