Most Effective RCM Software – Implementing RCM Engineering Strategies through the VAIL Plant

- February 7, 2023

- Posted by: Velosi Author

- Categories: HSE, Insights

RCM Engineering Software

Reliability Centered Maintenance Engineering contributes to one of the most proficient ways to optimize assets through effective maintenance strategies. It is not always about performing unnecessary maintenance activities. However, prioritizing them based on performance and functioning is the key. In addition, RCM engineering comprehends proficient analysis through FMEA/FMECA (failure modes effects and criticality analysis).

Innovate with RCM Software – VAIL Plant

As advancements are taking over, every industry is shifting its paradigm to digitalization. Reliability Centered Maintenance Software encompasses tools that identify and analyze the consequences of failure of any asset/system within an organization that further implement strategies to prevent failures that may affect organizational integrity.

Velosi’s advanced RCM software – VAIL Plant incorporates effective tools that assist in regulating the RCM engineering approach at its best. VAIL Plant software tools are implemented in a systematic way to enhance asset reliability, reduce maintenance costs, increase machine uptime, and gain a relevant understanding of elevated business risks. As discussed in the previous article, preventive maintenance is one of the most effective parts of RCM engineering that executes innovative strategies to keep up with safe and reliable asset maintenance.

Velosi offers superlative reliability-centered maintenance services to clients worldwide. Our RCM engineering experts utilize a systematic approach to apply industries’ best practices SAE JA1011, SAE JA 1012, BS EN IEC 60812, OREDA, and ISO-14224 to identify and analyze asset failures with cost-effective strategies.

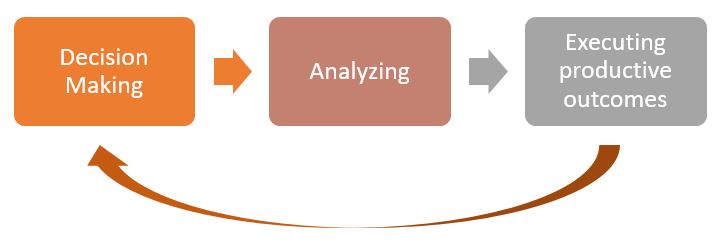

Three Vital Steps Contributing to Implement RCM Software

- Decision Making

Initially, this phase is important to carefully identify and analyze asset/system failures based on their complexity, the complex ones shall be sorted out instantly as they may pose a negative impact on overall organizational productivity.

- Analyzing

The second step is to analyze the identified asset/system failures to prevent them from reoccurring. During this phase, the root cause of failures is critically evaluated to prevent them in the future. The reoccurrence of failures within an organization is a serious threat to organizational integrity.

- Executing productive outcomes

Lastly, productive outcomes are carried out with help of the decision and analysis phase to minimize and eliminate the consequences of failure.

Please contact us for more information and assistance.