- March 24, 2025

- Posted by: Velosi Author

- Categories: CMMS, Insights, Software

Introduction to CMMS For Manufacturing

Downtime is the number one enemy of any production facility; equipment breakdowns are a nuisance and a real threat to the company’s profits. That is why choosing the right CMMS for manufacturing is not just another ordinary decision, it is a business-critical decision that affects the company’s profitability.

Why Current Maintenance Strategies are Inefficient in Manufacturing Enterprises

If you are still using spreadsheets or some other generic maintenance management tool, you are probably experiencing the following issues:

- Your maintenance team is burdened with documentation while strategic equipment remains idle.

- Your parts inventory is either gathering dust and consuming working capital or disappearing at a critical time.

These are not just normal problems; they are problems that sink into the bottom line and worsen over time.

What Makes a Good CMMS for Manufacturing Different from the Rest

Not all maintenance software is created equal. While an uncomplicated CMMS for manufacturing solutions may suit minor operations, manufacturing firms require unique features that are relevant to production circumstances.

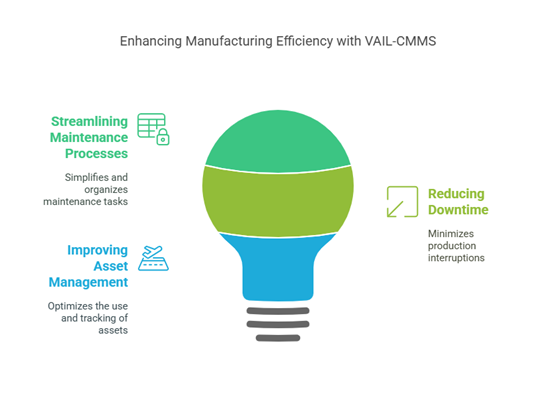

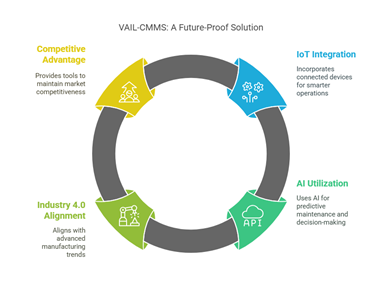

VAIL-CMMS is developed in compliance with the manufacturing industry. While other generic systems may approach all maintenance the same, VAIL-CMMS integrates a CMMS for manufacturing, understanding how downtime is directly linked to the bottom line.

The difference? VAIL-CMMS links with your production applications to establish a maintenance plan that syncs with your process. This is not just maintenance management; this is production support.

Real Solutions to Your Most Important Maintenance Issues

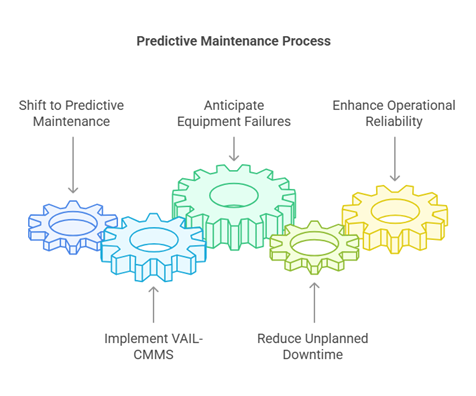

From Reactive Panic to Predictive Control

Imagine knowing a certain motor is starting to fail before it breaks down and disrupts your production line during an important order fulfillment. This is the level of comfort that VAIL-CMMS users leverage regularly. Organizations were able to decrease their unplanned downtime by 47% by identifying equipment problems before they became production crises.

Work Orders That Fit CMMS for Manufacturing

Production does not stop for maintenance – unless it has to. VAIL-CMMS arranges work orders based on the object’s criticality, the impact on production, and available resources.

This means your maintenance team is working on what is important and not just on what is next in the queue.

It can never be too many (or too few) parts. Why?

Inventory management is a challenge that is familiar to every maintenance team. VAIL-CMMS solves this problem by studying the equipment history, failure rates, and lead time to determine the best level of inventory.

Compliance Documentation That Practically Writes Itself

The last thing you want to do is chase after documents. VAIL-CMMS® produces the reports you need for ISO, FDA, OSHA, and other standards to make sure that you are always ready.

Mitigating Production Interruption in CMMS For Manufacturing

We know how it is – introducing new software while keeping production levels up seems challenging. That is why VAIL-CMMS® has an implementation process that is suited for busy manufacturing organizations:

- First, we take the time to get to know your unique production environment and your main concerns concerning maintenance.

- We set up the system to match your current processes, not the other way around.

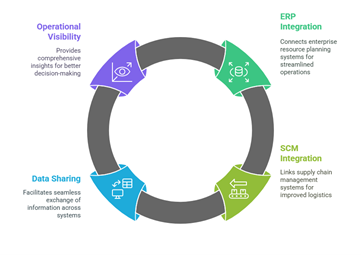

- We integrate with your production systems to give you a single view.

- We train your team by highlighting various potential manufacturing complications.

- We offer ongoing support with a focus on continuous process improvement.

Most of our manufacturing clients are up and running within weeks, not months.

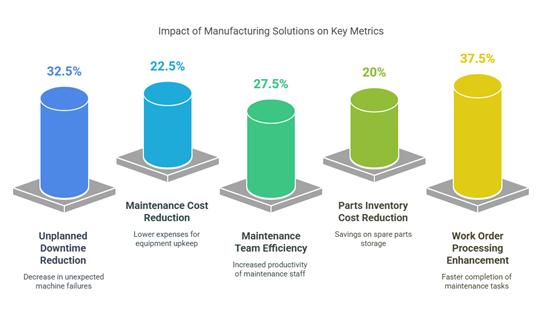

The Numbers That Matter: VAIL-CMMS® ROI

Here are the figures that matter. The typical return on investment that our manufacturing clients get:

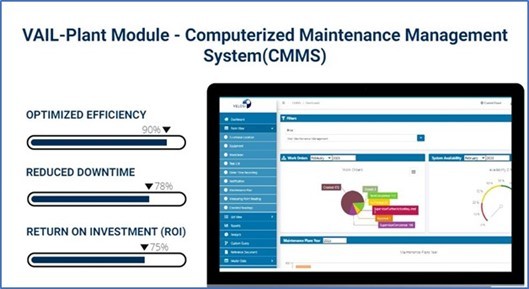

– Optimized Efficiency by 90%

– Reduced Downtime by 78%

– Return on investment (ROI) by 75%

What Makes Manufacturing Professionals Choose VAIL-CMMS®

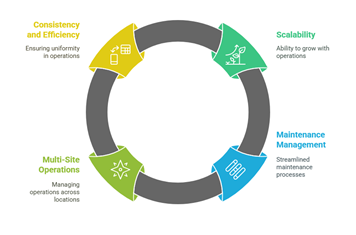

When you assess the CMMS options for manufacturing, VAIL-CMMS stands out because:

It was designed for production environments by people who have a production understanding.

Seamless compatibility with other software.

Expanding with operations across various sites.

Ongoing developments to match the industry 4.0 technology.

Take Control of Your Manufacturing Maintenance with the Perfect CMMS for Manufacturing Software Solution

In the modern manufacturing environment, maintenance can no longer be seen as a support function, it has to become a strategic asset. VAIL-CMMS® transforms your maintenance department into a strategic partner that works to achieve production objectives.

Are you interested in how VAIL-CMMS® can improve your downtime and profitability? Request a demo today!

Stay connected for more blogs!

Please contact us for more information and assistance.