- September 6, 2024

- Posted by: Velosi Author

- Categories: CMMS, Insights, Software

Introduction

Maintenance management as a whole should be effectively developed by overall maintenance management efficiency, one of the factors of critical importance for all industries and especially for organizations working with complex equipment, such as the oil and gas industry is an efficient management system. Computerized maintenance management systems (CMMS) are designed to reduce maintenance time by the efficiency in the design of maintenance operation planning and scheduling processes. In this blog, we will further explore all the major CMMS benefits that organizations can value when searching for ways to boost operational efficiency and reduce the size of operating costs.

-

Enhanced Maintenance Scheduling

One of the foremost advantages of CMMS is its ability to automate and optimize maintenance schedules:

– Automatically creates and tracks work orders.

– Prevents delayed or missed maintenance.

– Minimizes human error in scheduling.

Through automation of these tasks, CMMS can greatly enhance the longevity of machinery while preventing situations where equipment malfunctions.

-

Reduced Equipment Downtime

Reducing downtime is crucial for minimizing costs and maintaining productivity:

– Using real-time analysis of performance and data from previous operations, CMMS foresees maintenance requirements.

– Alert maintenance teams to potential issues before failure occurs.

– Proactively reduces unplanned downtime, saving both time and money.

Maintenance functions such as preventive and predictive maintenance make certain that equipment stays in use for a longer time, thus increasing efficiency.

-

Improved Asset Lifecycle Management

Effective management of asset lifecycles is another key CMMS benefit:

– Tracks each asset from purchase through to decommissioning.

– Maintains detailed maintenance records for better decision-making.

– Extends asset lifespan and enhances controlled return on investment (ROI).

This critical feature within CMMS benefits ensures equipment is either repaired, replaced, or retired at the right time, maximizing the value of your investments with greater productivity.

-

Cost Efficiency and Resource Optimization

CMMS drives cost savings and optimizes resource usage:

– Ensures maintenance is performed by the right personnel with the right tools.

– Reduces overstaffing or underutilization of resources.

– Minimizes unplanned repair costs by preventing major equipment failures.

Better resource management leads to increased cost efficiency across operations.

-

Enhanced Compliance and Reporting

Compliance with industry regulations is easier with CMMS:

– Automates documentation and tracking of safety inspections.

– Generates compliance reports efficiently.

– Minimizes the risk of over-cost penalties due to regulatory non-compliance.

One of the most critical CMMS benefits is effortlessly maintaining accurate records to remain compliant within the oil and gas industry.

-

Real-Time Data and Analytics

Data-driven decision-making is possible with CMMS:

– Provides real-time insights into asset performance.

– Analyzes maintenance history for better planning.

– Identifies trends that optimize maintenance strategies.

This data allows companies to adjust schedules and resource allocation to improve operational efficiency.

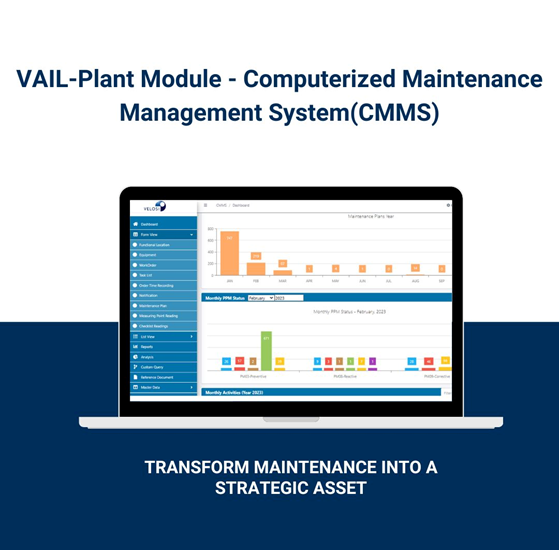

How VAIL-CMMS Can Assist the Oil and Gas Industry

For the oil and gas industry, VAIL-CMMS provides tailored solutions to meet the sector’s complex needs:

– Offers features specifically for managing large-scale assets like pipelines.

– Helps in the process of monitoring specific equipment in real-time and for predictive maintenance.

– Guarantees that all procedures and processes in the production follow safety measures that are permitted by the relevant industry.

VAIL-CMMS is a solution that benefits the oil and gas providers, decreasing the possibility of downtimes, extending the lifecycle of critical assets, as well as ensuring compliance and minimizing risks for the clients. By adopting VAIL-CMMS, organizations’ maintenance activities can be enhanced for improved organizational sustainability and profitability in the long-run.

Conclusion

In conclusion, CMMS is essential for any organization as it helps to streamline work schedules, minimize time wastage through breakdowns, optimize asset usage, and ensure that the organization complies with various regulations. Hence, for industries like the oil and gas industries, VAIL-CMMS offers an innovative solution that meets the needs of the industry. The implementation of a CMMS solution such as VAIL-CMMS shall not only enhance efficiency of maintenance but also enhance business performance.

Stay connected for more blogs!

Please contact us for more information and assistance.