A Quick Overview of RCM (Reliability-Centered Maintenance)

- February 4, 2023

- Posted by: Velosi Author

- Categories: HSE, Insights

Introduction to RCM

Reliability-Centered Maintenance is a systematic technique that utilizes effective tools for identifying, managing, and implementing suitable maintenance strategies for assets in your organization. The main purpose of RCM is to ensure your organizational assets are performing efficiently based on users’ needs and convenience.

Over the years, industries have gone through a massive evolution. As advanced resources and technology are taking the lead, it is however getting difficult to prevent and mitigate the consequences of failure. This is where RCM sets forth effective strategies to optimize asset maintenance safely and productively. Moreover, systematic maintenance techniques predominantly execute cost-effective outcomes by retaining asset reliability and affordability.

RCM: Overcoming Standard Maintenance Programs

The word RCM (Reliability Centered Maintenance) itself portrays relevancy through “reliability” and “maintenance” which focus on quality performance and proper functioning of the asset.

Every organization incorporates a variety of assets performing different functions at various time intervals. Should organizations prioritize assets and their performance accordingly? The answer is yes. RCM has the ability to identify and manage organizational assets on a priority basis with effective decision-making. Getting into a little more detail, some assets might be more critical than others might during daily processes and RCM lays out a foundation for prioritizing, optimizing, and assigning maintenance tasks through advanced predictive maintenance technologies. Therefore, nowadays organizations are taking over advanced maintenance practices by implementing RCM methodology worldwide.

Key Features of Implementing RCM (Reliability-Centered Maintenance)

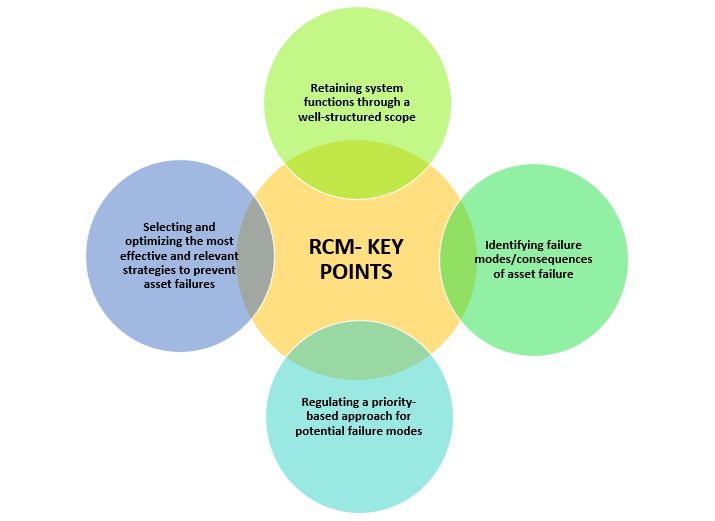

When organizations regulate the RCM approach, it is paramount to execute maintenance activity on a priority basis. Another factor to be kept in mind is the prevailing high costs surpassing overall benefits. Additionally, RCM revolves around four critical key points.

When it comes to reliability-centered maintenance, there are various techniques to implement this methodology. RCM can relate to Failure Modes and Effects Analysis (FMEA) by comprehensively identifying and analyzing the probability of potential failures based on system design and culture to safeguard organizational asset integrity.

Other techniques include:

- Preventive Maintenance (PM) Optimization,

- Reliability-Based Maintenance Optimization

- Reliability Enhanced Maintenance Optimization

The following are foreseen circumstances to productively analyze and implement the most suitable maintenance strategy:

- Consequences of failure

- Probability of failure

- Historical data available

- Risk tolerance

Top Six Benefits of RCM

- Creating Rational Optimal Maintenance Plans

Reliability Centered Maintenance sets forth a rational analysis of the consequences of failure that assists organizations to implement effectively planned maintenance strategies. Effective optimization through RCM generates potential cost cut down and maintains asset reliability and integrity.

- Setting priority-based maintenance activities

As discussed earlier, RCM is responsible for mitigating the consequence of a failure of assets/systems. It has the proficiency to optimize maintenance activity on a priority basis because not all assets require instant maintenance depending on their functionality and performance.

- Minimizing overhead costs

Unnecessary maintenance costs are eliminated with the RCM methodology to gain a better return on investment with other associated benefits.

- Enhancing team building and client relationships

RCM is not based on a one-man army approach. It involves a team to identify, analyze, and implement cost-effective maintenance strategies to keep up with asset reliability.

- Maintaining health and safety integrity

Failures can take place in every organization, and mitigating risk can contribute to safeguarding the health and safety of the surrounding.

- Improving overall asset integrity

Eliminating expendable overhead costs and unnecessary maintenance activity reduces potential failures and unexpected shutdowns at the workplace, maintaining effective asset reliability and integrity.

Please contact us for more information and assistance.