- January 14, 2025

- Posted by: Velosi Author

- Categories: Asset Integrity, Insights

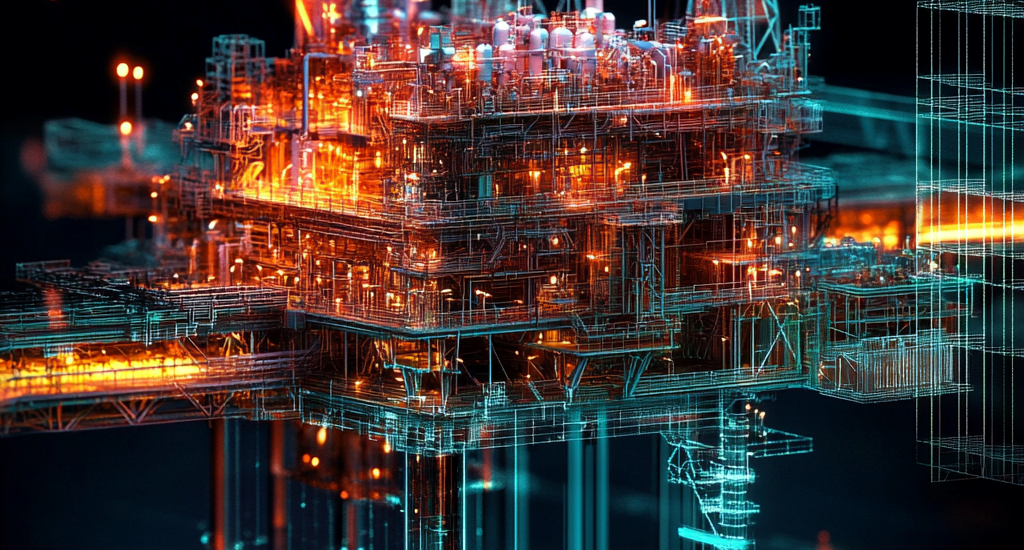

Structural integrity management in the oil and gas industry is not just a technical term; it is the foundation of safety, efficiency, and dependability in operational and technical activities. Exploring unfavorable and challenging conditions, including the deep offshore or extremely onshore climate, requires effective systems of structural integrity management. At Velosi, we have refined expertise in this area, using international standards to provide high-quality services.

Understanding Structural Integrity Management

Structural integrity management is defined as the overall strategy used for the maintenance of structures in order to be able to handle working and environmental loads throughout the structure’s life cycle. In the oil and gas sector, this means sustaining the integrity and performance of assets to comply with highly prescribed regulatory directives. Overlooking structural implications leads to disastrous consequences, risks to the environment, losses, and disruptions.

Effective structural integrity management encompasses:

- Material Analysis: Ensuring that materials used can endure harsh conditions.

- Design Optimization: Creating structures resilient to environmental challenges.

- Regular Monitoring: Using advanced tools to detect wear and tear early.

- Proactive Maintenance: Addressing issues before they escalate into costly problems.

The Four Phases of Structural Integrity Management

- Design Phase: At the outset, engineers assess potential operational and environmental stresses, creating structures designed to meet these challenges. Risk assessments and simulations help in crafting reliable, long-lasting assets.

- Construction Phase: This phase emphasizes quality assurance. Following international standards ensures the structural components are built to withstand expected demands.

- Operational Phase: Continuous monitoring and regular maintenance are essential to manage wear and tear. Tools like VAIL-Plant® streamline inspection schedules and provide actionable insights.

- Decommissioning Phase: Safely dismantling structures at the end of their lifecycle minimizes risks and aligns with environmental compliance standards.

Why International Standards Matter

Global standards play a critical role in effective structural integrity management. Velosi adheres to industry-leading codes, including:

- ISO 19900: General requirements for offshore structural design and assessment.

- ISO 19902: Guidelines for fixed steel offshore structures.

- ISO 19904: Standards for floating offshore platforms.

- API RP 2 SIM: A framework for managing offshore platform integrity.

These standards not only ensure safety and reliability but also promote efficiency by providing a clear, concise strategy for best practices.

Managing a Variety of Structures

Velosi’s expertise explores a wide range of structural types, each requiring tailored management strategies:

- Offshore Platforms—Subsea Structures: These structures endure immense pressures and corrosive conditions, necessitating precise monitoring.

- Offshore Platforms—Topside Structures: Vital equipment and personnel, these platforms demand high structural resilience.

- Floating Production Storage and Offloading (FPSO): FPSOs require specialized management for hulls and flexible risers to maintain safety and efficiency.

- Onshore Structures: Onshore assets, from pipelines to processing plants, pose several challenges that require regular integrity assessments.

The Role of VAIL-Plant® in Structural Integrity Management

Velosi’s proprietary system, VAIL-Plant®®, revolutionizes structural integrity management by combining advanced technology with practical functionality. It seamlessly integrates Risk-Based Inspection (RBI) and Failure Modes, Effects, and Criticality Analysis (FMECA) to optimize inspection management and flow processes. By prioritizing high-risk areas through RBI and addressing potential failure modes with FMECA, VAIL-Plant® ensures enhanced asset reliability and cost-effective maintenance strategies.

Key features include:

- Real-Time Monitoring: Gain instant insights into structural health.

- Automated Inspections: Streamline and schedule integrity checks efficiently.

- Compliance Integration: Ensure full adherence to international standards.

- Enhanced Productivity: Identify and address potential issues proactively, reducing downtime and maintenance costs.

Through our customized VAIL-Plant® integration, organizations can transition from reactive to proactive maintenance strategies, safeguarding their assets while optimizing operational efficiency.

Advanced Tools for Structural Integrity Management

Velosi is the leading Structural Integrity Solutions Provider, using advanced tools and methodologies. Ranging from non-destructive testing methods to predictive analysis with the application of artificial intelligence, it provides holistic monitoring of assets. VAIL-Plant® is an example of the systems that facilitate decision-making processes that enhance the safety and performance of the systems.

Sustainability Through Structural Integrity Management

Nowadays, sustainability is not an option but a necessity for organizations to retain their loyal position in the industry. Properly executed structural integrity management has been shown to reduce waste, enhance asset life, and reduce adverse environmental effects.

For instance, early corrosion detection in offshore platforms is a systematic, cost-effective strategy and prevents significant environmental damage. Velosi’s sustainability strategies are consistent with the best-known approaches to global practice today. They assist businesses in a more eco-friendly-directed business environment.

Enhancing ROI with Structural Integrity Management

Investing in advanced structural integrity management delivers tangible benefits:

- Reduced Downtime: Minimized failures ensure uninterrupted operations.

- Cost Savings: Proactive maintenance lowers repair and replacement costs.

- Regulatory Confidence: Automated compliance simplifies audits and reporting.

By prioritizing structural health, organizations not only safeguard their assets but also achieve operational and financial efficiency.

Conclusion

To conclude, efficient structural integrity management can lead to a safe, efficient, and sustainable business in the oil and gas industry. Innovative solutions integrated within the VAIL-Plant® Structural Integrity Management System recognize relevant standards and ensure optimum asset lifecycle reliability.

Stay connected for more blogs!

Please contact us for more information and assistance.