Advantages of 3D CAD (Computer Aided Design) Modelling in Engineering

- January 31, 2022

- Posted by: Velosi Author

- Categories: Engineering, Insights

Computer Aided Designs: Design and plans are critical components of a wide variety of sectors, including engineering, architecture, construction, and manufacturing. These models’ blueprints are an important element of the building process since they provide critical data such as size, dimension, and material information.

Due to the size and complexity of projects, the need for detailed design and documentation cannot be understood in the area of operations and maintenance (O&M), especially in the oil and gas sector.

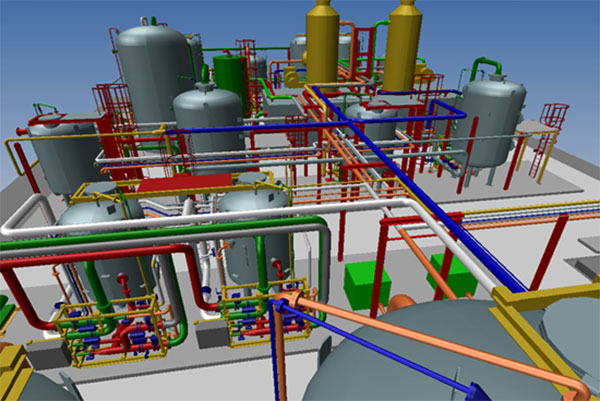

Advanced software and 3D designs are critical for operational readiness and asset building for plants, whether it’s basic plant engineering, piping design, stress analysis of piping, commissioning design review and detailed engineering services, or data access from facility engineers to the O&M team. As the industry moves forward with digitization, the importance of 3D CAD modeling is becoming increasingly evident.

With growing global competition, rising costs, and uncertain energy prices, there is a strong focus on profitability via leaner projects and faster turn-around times. The oil and gas industry has become more dependent on data and technology to maintain a competitive edge.

Evaluate the following advantages of 3D modelling in engineering for optimizing operational efficiency.

What are the advantages of 3D CAD Modelling?

The below-mentioned are some of the major benefits of 3D CAD modelling in detail.

- Simple and Efficient pipeline design

Through the use of user-friendly pipe routing, 3D design modelling allows the iteration process to be simplified. By combing the sophisticated capabilities of 3D CAD software with engineering and design input, it is possible to create complete 3D pipelines with appropriate fittings from sketched routes that include all materials required.These 3D software tools with interactive 3D drawings enable component conformity to specified characteristics like diameter, pressure, and others, resulting in highly accurate pipeline design and process reliability. - Greater visualization for clients

3D CAD modelling software helps major plant design disciplines save time and money. It allows owner-operators and engineering, procurement, and construction (EPC) firms to have a clearer picture of the entire plant and the power to make informed, data-driven choices and predictions. Moreover, customers have to face numerous ‘what-if’ situations during the design process. The development of virtual models allows stakeholders who are not familiar with CAD or design to participate in the process. - Improves designer performance

3D CAD modelling optimises designer output by eliminating the manual and laborious aspects of design. It enables the designer to see all components in 3D at the original design stage and to quickly modify them if necessary. This minimizes iteration process and increases designer productivity. - Compatibility with international codes and standardsWith 3D CAD modelling, compliance with international codes and standards for different processes and plant design becomes much simpler, since specifications for each standard, such as BSI, ANSI, DIN, CSN, GB, and ISO, are integrated. Sticking to industry standards facilitates internal communication and results in improved productivity.

- Documentation3D modelling in engineering improves your data management capabilities by allowing you to organize and manage your design assets and documentation more effectively. It allows you to standardize your detailing and drawing processes, automating your workflow and improving output speed and accuracy.Furthermore, automatic ISO creation aids in material consumption, accuracy and procurement, and manufacturing time efficiency.

- High-Quality deliverables and cost-effective timeEngineering procurement and construction firms are under tremendous pressure to fulfil global demand in a hostile and competitive market. Plant design software has improved in terms of capability, complexity and scope, enabling these businesses to generate high-quality outputs on a tight schedule and within a limited budget.Besides, by advancing early idea layouts into detailed engineering, 3D modelling decreases remodelling between conceptual and detailed design.

- IntegrationAdvanced 3D CAD software, enables the precise extraction of GA, layouts, Isometric drawings, cable routing, BOM, steel and architectural drawings, and other documents from a single file. It also provides a clear understanding and enhanced control over design and quality in a variety of fields.

Conclusion

All things considered, these benefits of 3D CAD modelling in engineering streamline the whole design and development process, from ideas through planning, precise designs, and consultation papers. Numerous top plant design and 3D modelling software packages provide advanced capabilities and a variety of customised advantages based on the complexity and the scale of the projects. Intergraph PDS, AVEVA PDMS, AutoCAD Plant 3D, Bentley, and SolidWorks are only a few of the top software packages.

Are you searching for cost-effective design solutions possible via 3D CAD engineering? Velosi Asset Integrity has demonstrated expertise in multi-disciplinary 3D drawing and modelling solutions for large-scale projects. Contact us to find out more.