Safety Integrity Level (SIL)

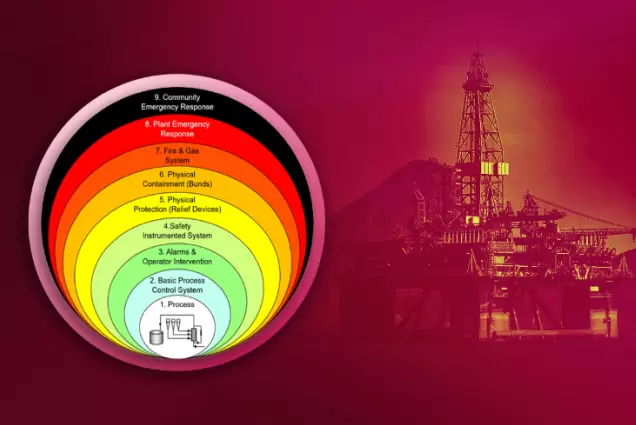

Safety Integrity Level (SIL) is an analysis or measurement of performance required for a Safety Instrumented Function (SIF) to maintain or achieve a safe state. At Velosi, we understand that it is crucial to perform a statistical measurement of how likely a process or a system is to be operational and ready to serve the function for which it is intended, including the calculated time to its likelihood of failure. Our uniquely designed SIL study services comply with global standards – IEC-61508, IEC-61511 and ISA TR 84.00.02 – to ensure the safe and reliable operation of the plant.

SIL is performed for the Safety Instrumented Systems (SIS). A Safety Instrumented System is for the protection of equipment consisted of Initiator, Logic Solver and Final Elements. A specific reliability is required from these components depending on the risk that the SIS is to reduce. SIL is the statistical representation of the reliability of the SIS (safety instrumented system), when a process demand occur.

Read more

Benefits of SIL

Effectively manages safety-critical equipment.

Prevents or mitigates the consequences which can result in mishaps like loss of life, personnel injury, equipment damage or loss of production.

SIL Deliverables

SIL Methodology

SIL Classification

SIL Verification

Safety Requirement Specification (SRS)

Safety Life Cycle Document

SIL Software

Prioritize, Redefine Asset Integrity with our extensive VAIL- PHA® Software

VAIL- PHA® is Velosi’s proprietary software and is built to execute all stages of SIL Classification, SIL Verification and preparation of Safety Requirement Specifications (SRS). The software also supports testing interval and Spurious Trip Rate (STR) calculations of SIFs.