The Importance of Compressive Strength Test

- September 3, 2023

- Posted by: Velosi Author

- Categories: Civil, Insights

Introduction

Infrastructure projects are taking the lead as advancements are emerging. Building durable infrastructures is important and involves proper material testing with authentic regulations and standards. One of the most important tests conducted in the infrastructure industry is the Compressive Strength Test.

The compressive strength of a structure plays an important role in multiple purposes. It is constantly verified during the design and construction procedures of bridges, and other building structures made of materials such as steel, concrete blocks, cement, etc. to ensure safety and stability. Moreover, it is utilized to analyze the quality of materials such as concrete and rocks.

What is Compressive Strength?

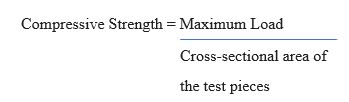

The compressive strength of a structure during testing involves a maximum stress or load that the material can withstand without getting damaged when compressive forces are constantly applied. The compressive strength of a material is determined by various factors, including:

- The material’s composition

- Density

- Microstructure

A precise example would be, a block of concrete/structure with a higher cement content and a denser microstructure will most likely have a higher compressive strength. Additionally, compressive strength test is measured in units of force per unit area, such as pounds per square inch (psi) or megapascals (MPa).

Importance of Compressive Strength Test

The compressive strength test is performed on a compression testing machine with set procedures to avoid any load testing damage. The specimen is placed between the platens of the machine and a load is applied gradually until the specimen fails.

The compressive strength of a material is important for a number of reasons. It is used to:

- Design and construct structures, bridges, and buildings.

- Assess the quality of concrete, rocks, and other materials.

- Select appropriate materials for specific applications.

- Predict the strength of materials under load.

- Develop new materials with enhanced properties.

Applications of Compressive Strength Test

The compressive strength test is used in the following five applications:

- Concrete testing: Used to assess the quality of concrete and to determine its suitability for specific applications.

- Rock testing: This type of testing is done to analyze the maximum compressive stress a rock sample or rock bed can resist up to. It is used to design structures based on the strength and deformation behavior of rock strata underneath. In-situ conditions of rock strata can vary due to environmental factors.

- Material testing: Tests compressive strength of a variety of materials, including metals, plastics, and composites.

- Structural engineering: Involves the process of designing and constructing buildings, bridges, and other structures.

- Quality control: Proficiently ensures that materials meet the specified quality standards.

Conclusion

To conclude, the compressive strength test proves to be an essential technique for the evaluation of infrastructures/structures that provide valuable information about the maximum compressive force a material can withstand plus its durability percentage. By efficiently assessing the compressive strength of materials such as concrete and rocks, engineers and architects can ensure that their designs are safe, durable, and sustainable. The compressive strength test is, therefore, a vital tool in the field of engineering and construction.

Please contact us for more information and assistance.