Key Features of Implementing Ultrasonic Thickness (UT) Gauging Technique

- January 12, 2023

- Posted by: Velosi Author

- Categories: Insights, NDT

What is Ultra Thickness (UT) Gauging?

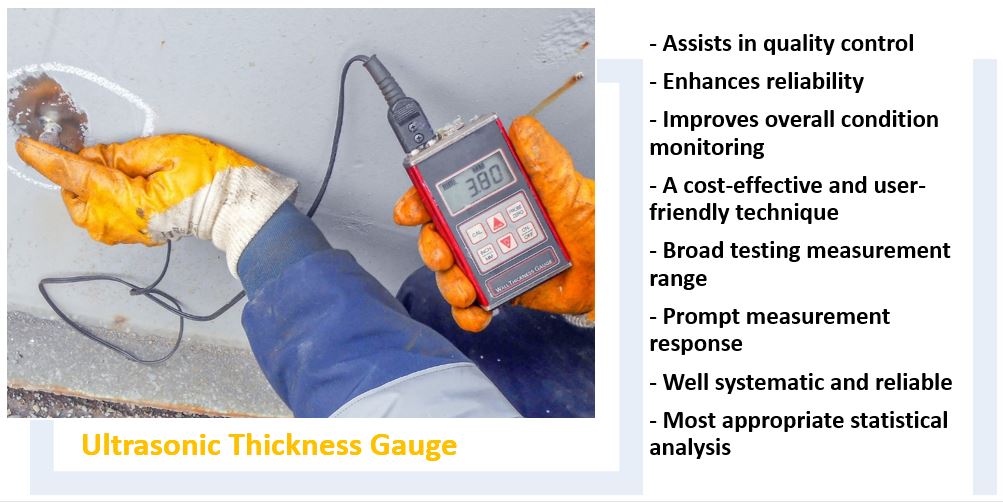

Ultrasonic Thickness Gauging is a testing technique that is used for the Non-Destructive investigation of materials and their thickness by ultrasonic waves. Materials are major components that make up any form of structure and material reliability should be an utmost priority. Note, the ultrasonic thickness gauging technique is utilized to enhance and ensure the safety and reliability of materials that can be put through negative situations, like corrosion or erosion.

This technique can also be utilized for ultrasonic thickness measurements (UMT) of solid elements within a structure. Mostly, the ultrasonic thickness gauge is employed to monitor steel thickness in offshore constructions and pipelines.

An Essential NDT Technique – Ultrasonic Thickness Gauge Testing

Overall, to avoid destruction or structural damage, it is highly critical to conduct appropriate Non-Destructive Testing techniques, further safeguarding the asset. Non-Destructive Testing ensures the safety and integrity of a structure. Moreover, neglecting substandard inspections can potentially lead to harmful hazards affecting overall functionality. In addition, detaining inspection and testing not only have an adverse impact on the specific structure but can also be a threat to the surrounding people and environment.

Implementation of Ultrasonic Thickness Gauge

The ultrasonic thickness gauge is not only used for material thickness testing but also to inspect other unclear limitations.

It is widely implemented for the following:

Inspects the wall depth of materials, especially the ones put through high heat and high pressure to avoid potential mishaps by outbreaks or leakages.

Corrosion leads to destruction with increased safety risks. The ultrasonic thickness gauge is used for testing and monitoring corrosion risks to ensure compliance with industry standards and nullifies time-to-time repairs, which makes the testing cost and time effective.

This technique is used to test any defects or damages in solid materials, as the ultrasonic thickness gauge is highly reliable and accurate; it assists in analyzing the pattern of solid material through ultrasonic waves.

Please contact us for more information and assistance.